Metals and alloys: Metals may be ferrous, non-ferrous metals and alloys.

Metals and alloys

- Ferrous Metals

- Non Ferrous Metals

- Alloys

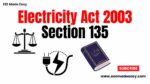

Ferrous metals

Ferrous metals are those which have iron as their base. They include iron and its alloys such as steel, cast iron and alloy steels such as stainless steel etc.

Non-ferrous metals

Non-ferrous metals do not contain iron as base. They include copper, aluminium, zinc,tin etc and non-ferrous alloys.

Alloys

If two or more metals are chemically combined they form an alloy e.g. iron, chromium nickel and carbon form an alloy called chromium nickel steel (stainless),manganese, iron and carbon form an alloy called manganese steel, copper and zinc form

an alloy called brass, copper and tin form an alloy called bronze, lead and tin form an alloy called soft solder.

- soft solder : Lead , tin

- Bronze: Copper,Tin

- Brass: Copper , Zinc

- manganese steel: manganese, iron,carbon

- chromium nickel steel (stainless steel): chromium nickel and carbon

Properties of metals

Properties of metals can be classified mainly into:

Chemical properties

Physical properties

Mechanical properties

Chemical properties

Chemical properties are those which involve chemical effect such as:

Corrosion

Oxidation

Reduction

Corrosion will spoil the metal surface due to the effect of various elements in the

atmosphere and water.

Oxidation is the formation of metal oxides which occur when oxygen combines with

metals.

Reduction refers to the removal of oxygen from the surrounding molten puddle to reduce

the effect of atmospheric contamination.

Physical properties

Physical properties are those, which affect metals when they are subjected to heat

generated by welding such as:

melting point

thermal conductivity

thermal expansion

grain growth

Melting point

Melting point is the degree of temperature, when a solid metal changes into liquid.

Melting points of some metals are given below:

Mild steel 1500 to 1530°C

Cast iron 1150°C

Copper 1083°C

Aluminium 659°C

Brass and bronze 850°C-950°C

Zinc 419°C

Tin 232°C

Lead 327°C

Nickel 1452°C

10 Soft solder

(50% lead, 50% tin)

Thermal conductivity

Thermal conductivity is the rate at which a metal conducts heat to the adjacent area of

the heated job. Copper conducts heat faster than aluminium. Aluminium conducts heat

faster than iron.

Thermal expansion

Whenever metals are heated there will be increase in its dimensions due to their thermal

expansion property. Depending on the nature of metal, different metals will have

different thermal expansion.

Grain structure

Like salt or sugar, the metal is also a crystalline substance. In metals the crystals are

called grains. Grains are composed of atoms. Atomic structure determines the grain

structure just as the arrangement of bricks determines the shape of the building. During

welding (due to heating effect) the grain size increases resulting in the loss of strength.

Mechanical Properties

Mechanical properties are those which determine the behavior of metals under applied

load such as:

Tensile strength

Ductility

Hardness

Toughness

Brittleness

Tensile strength is the property of the metal which resists forces acting to pull it apart.

Ductility is the ability of the metal to stretch, bend or twist without breaking or cracking

or to draw into fine wires.

Hardness is the ability of the metal to withstand abrasions, cutting action by a tool.

Usually any hard metal will resist the compressive forces. Normally a hard metal will

also be brittle.

Toughness is the ability of a metal to withstand sudden force without breaking.

Brittleness is the property of the metal which is opposite of ductility and is applied to a

metal which cracks suddenly if placed pressure or load to bend or twist.

Effect of welding heat on the properties of metals

During welding the properties of the weld metal may be affected.

Important alloying elements may be destroyed.

Brittle, hard or cracked welds may be produced.

There may be reduction in the corrosion resistance properties of the welds.

Main properties of the base metal and weld metal will get affected

Join EEE Made Easy Whatsapp Channel

Read more on Electric Welding

- [Set 2]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- [Set 1]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- Electric Welding|Resistance welding Electric Arc Welding

- Resistance Welding|Types of Resistance Welding

- Electric arc welding|Types of Electric Arc welding

- Electric Arc length|Short,Medium, Long Arc

- Open Circuit voltage and Arc voltage|Polarity in arc welding

- Arc Welding Equipments|Arc Welding tools and Accessories

- Arc welding safety|shielded metal arc welding preparation & safety

- Methods of joining metals|Metal Joining Methods

- Types of welds|Weld types

- Applications of Welding|Welding Applications

Books on Welding

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus