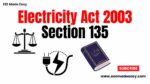

Electric arc welding: Electric arc welding is the process of joining two metallic pieces or melting of metal is obtained due to the heat developed by an arc struck between an electrode and the metal to be welded or between the two electrodes as shown.

In this process, an electric arc is produced by bringing two conductors (electrode and metal-piece) connected to a suitable source of electric current, momentarily in contact and then separated by a small gap, arc blows due to the ionization and give intense heat.

The heat so developed is utilized to melt the part of work-piece and filler metal and thus forms the weld. In this method of welding, no mechanical pressure is employed; therefore, this type of welding is also known as ‘non-pressure welding’.

The length of the arc required for welding depends upon the following factors:

- The surface coating and the type of electrodes used.

- The position of welding.

- The amount of current used.

Electric arc is formed when both the terminals of an electric circuit are brought

together and then separated by a small gap.

When high current passes through an air gap from one conductor to another, it produces very intense and concentrated heat in the form of a spark.

The temperature of this spark (or arc) is app. 3600°C, which can melt and fuse the metal very quickly to produce a homogeneous weld

Various types of electric arc welding are:

- Carbon arc welding

- Metal arc welding

- Atomic hydrogen arc welding

- Tungsten inert gas arc welding (TIG)

- Gas metal arc welding (GMAW) or Metal inert gas arc welding (MIG)

- Submerged arc welding

- Electro-slag welding

- Plasma arc welding

- Shielded Metal Arc welding

Download & Install EEE Made Easy App

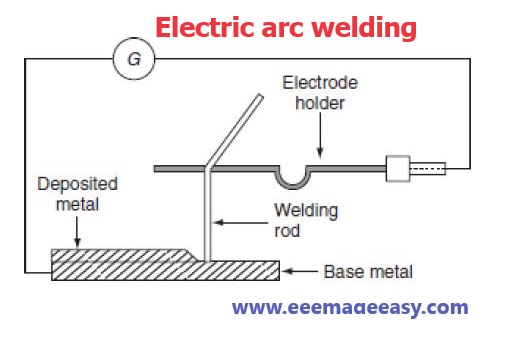

1. Carbon arc welding

It is one of the processes of arc welding in which arc is struck between two carbon electrodes or the carbon electrode and the base metal.

The simple arrangement of the carbon arc welding is shown in Figure.

In this process of welding, the electrodes are placed in an electrode holder used as negative electrode and the base metal being welded as positive.

Unless, the electrode is negative relative to the work, due to high temperature, there is a tendency of the particles of carbon will fuse and mix up with the base metal, which causes brittleness; DC is preferred for carbon arc welding since there is no fixed polarity maintained in case of AC.

In the carbon arc welding, carbon or graphite rods are used as electrode.

Due to longer life and low resistance, graphite electrodes are used, and thus capable of conducting more current.

The arc produced between electrode and base metal; heat the metal to the melting temperature, on the negative electrode is 3,200°C and on the positive electrode is 3,900°C.

This process of welding is normally employed where addition of filler metal is not required.

The carbon arc is easy to maintain, and also the length of the arc can be easily varied.

One major problem with carbon arc is its instability which can be overcome by using an inductor in the electrode of 2.5-cm diameter and with the current of about of 500–800 A employed to deposit large amount of filler metal on the base metal.

Filler metal and flux may not be used depending upon the type of joint and material to be welded.

Advantages of carbon arc welding

•The heat developed during the welding can be easily controlled by adjusting the length of the arc.

•It is quite clean, simple, and less expensive when compared to other welding process.

•Easily adoptable for automation.

•Both the ferrous and the non-ferrous metals can be welded. Disadvantages

•Input current required in this welding, for the work-piece to rise its temperature to melting/welding temperature, is approximately double the metal arc welding.

•In case of the ferrous metal, there is a chance of disintegrating the carbon at high temperature and transfer to the weld, which causes harder weld deposit and brittlement.

•A separate filler rod has to be used if any filler metal is required.

Applications of carbon arc welding

It can be employed for the welding of stainless steel with thinner gauges.

•Useful for the welding of thin high-grade nickel alloys and for galvanized sheets using copper silicon manganese alloy filler metal.

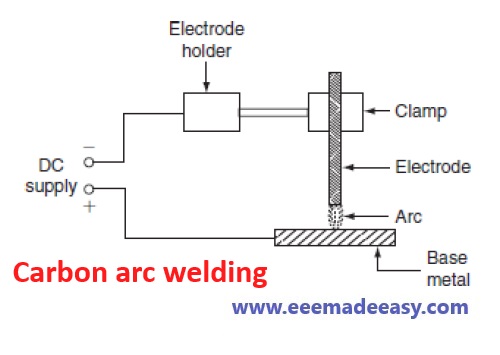

2. Metal arc welding

In metal arc welding, the electrodes used must be of the same metal as that of the work-piece to be welded.

The electrode itself forms the filler metal.

An electric arc is stuck by bringing the electrode connected to a suitable source of electric current, momentarily in contract with the work-pieces to be welded and withdrawn apart.

The circuit diagram for the metal arc welding is shown in Figure

3. Atomic hydrogen arc welding

In this process the arc is formed between two tungsten electrodes in an atmosphere of

hydrogen gas.

The welding job remains out of the welding circuit and a separate filler rod is used to add the filler metal.

4. Tungsten inert gas arc welding (TIG)

In this process the arc is formed between the tungsten electrodes (nonconsumable) and the welding job in an atmosphere of an inert gas (argon or helium). A

separate filler rod is used to add the filler metal. This process is also called gas tungsten

arc welding (GTAW) process

5. Gas metal arc welding (GMAW) or Metal inert gas arc welding (MIG)

In this process the arc is formed between a continuous, automatically fed, metallic

consumable electrode and welding job in an atmosphere of inert gas, and hence this is

called metal inert gas arc welding (MIG) process.

When the inert gas is replaced by carbon dioxide then it is called CO2 arc welding or metal active gas (MAG) arc welding.

The common name for this process is gas metal arc welding (GMAW).

6. Submerged arc welding

In this process the arc is formed between a continuous, automatically fed, metallic

consumable electrode and the welding job under a heap of powdered/ granulated flux.

The arc is totally submerged in the flux (invisible).

7. Electro-slag welding

The arc is formed between a continuous, automatically fed, metallic consumable electrode and the welding job under a thick pool of molten flux (slag).

This automatic process requires special equipment and is used only in vertical position for the welding of heavy thick plates.

8. Plasma arc welding

In this process the arc is formed between a tungsten electrode and the welding job in an atmosphere of plasma-forming gasnitrogen, hydrogen and argon.

A separate filler rod is used to add the filler metal in the joint, if necessary.

But normally no filler rod is used.

The process is similar to TIG welding.

Plasma cutting is used to cut non-ferrous metals and alloys successfully and quickly

9.SHIELDED METAL ARC WELDING (SMAW)

Salient Features

It is an arc welding process in which the heat required for the welding comes from

an electric arc.

The electric arc develops when electricity jumps across an air gap (ionization of air)

between the end of the metallic electrode and the welding job surface.

The metallic electrode is generally coated with a flux which is consumable.

The arc created due to the ionization of air between the electrode tip and the base

metal generates an intense arc heat having a temperature between 3600°C-4000°C.

The welding current is provided by an AC or DC machine.

The intense heat of the arc melts a small portion (molten pool) on the job directly

under the arc and at the end of the electrode instantaneously.

The melted electrode fuses into the molten pool of the welding job and produces a

homogeneous weld on cooling.

The flux coating on the electrode also melts and provides a gaseous shield around the arc which protects the molten metal from atmospheric contamination. Hence this is called

shielded metal arc welding (SMAW).

The welding speed and feed of the electrode is controlled manually by the welder himself. So it is also called manual metal arc welding (MMAW).

When the weld metal solidifies, the slag (of flux coating) gets deposited on its surface as it is lighter than the metal and the weld metal is allowed to cool gradually

and slowly.

Advantages of shielded metal arc welding

The process is widely used because of the following advantages:

All kinds of light and heavy gauge metals can be welded.

It can be used for fabrication, construction as well as maintenance works.

All types of metals (ferrous, non-ferrous and alloys) can be welded.

It permits a skilled operator to perform the welding operation quickly and easily.

It is more suitable for short length welds.

It is less expensive than the other processes.

It is less sensitive to weld than the other arc welding processes.

It is portable.

Limitations of shielded metal arc welding

Less metal is deposited per hour and so can not be used for heavy fabrication welding.

Requires more welders to be employed.

Controlling the distortion is difficult.

Continuous and automatic welding is not possible due to the specific length of the

electrode.

More strain to the welder.

Applications of shielded metal arc welding

It is used for welding thin gauge as well as thick gauge metals in small and medium scale industries.

Used in welding bridges, bus bodies, domestic items like grills for gate, windows, doors, chairs and tables.

Used in welding roof structures for workshops, broken and cracked castings, water and oil tanks.

Whenever welding is done in outdoor work, this process is very useful as a diesel generator welding set can be used.

This process is used for reconditioning, hard facing, rectifying broken parts and repair welding.

Read more on Electric Welding

- [Set 2]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- [Set 1]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- Electric Welding|Resistance welding Electric Arc Welding

- Resistance Welding|Types of Resistance Welding

- Electric arc welding|Types of Electric Arc welding

- Electric Arc length|Short,Medium, Long Arc

- Open Circuit voltage and Arc voltage|Polarity in arc welding

- Arc Welding Equipments|Arc Welding tools and Accessories

- Arc welding safety|shielded metal arc welding preparation & safety

- Methods of joining metals|Metal Joining Methods

- Types of welds|Weld types

- Applications of Welding|Welding Applications

Books on Welding

Join EEE Made Easy Telegram channel

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus