EEE Made Easy Latest Posts

- Syllabus Training Instructor Plumber|14/2025 Syllabus Kerala PSC

- [PDF] Syllabus AE KSEB Transfer|378/2025 Syllabus Kerala PSC

- Modified Harvard Architecture

- TMS320C5X Architecture

- Advantages of Digital Signal Processing

- [PDF] AE Agro Industries Corporation syllabus|595/2024 syllabus Kerala PSC

- Tellengen’s Theorem & Example

- TOD Meter or Time of Day Meter

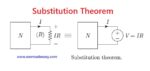

- Substitution Theorem & Examples

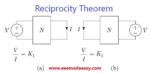

- Reciprocity Theorem with Examples

- MCQs Basic Computing|Computer MCQ

EEE Made Easy is providing free study materials on Electrical and Electronics Engineering through EEE Made Easy Website & free Electrical classes on EEE Made Easy Youtube Channel. EEE made Easy provides Seminar report preparation for students on demand. EEE Made Easy also provides paid courses for Electrical Competitive exams like RRB JE Electrical Coaching in Kerala,Sub Engineer, Assistant Engineer, Lecturer and Assistant professor in Electrical Engineering.

Download & Install EEE Made Easy App

Download & Install EEE Made Easy App

Courses Offered by EEE Made Easy

- RRB JE Electrical (Whatsapp message on 7510893107)

- Sub Engineer Electrical KSEB (Whatsapp message on 7510893107)

- Assistant Engineer(AE) Electrical

- Polytechnic Lecturer (Whatsapp message on 7510893107)

- Assistant Electrical Inspector

- Instructor Grade I and II Electrical

- Electrician

Syllabus of Competitive Exams

CLICK HERE for Syllabus PDF Download

EEE Notebook Notes

Electrical Notes From Notebook

These are from EEE Made Easy Old Website

EEE Made Easy Video Classes

Attend Quizzes

Click HERE

Here, we have provided MCQ Questions on Basic Electrical Engineering Topics. Basic Electrical MCQ’s from Notebook Site and EEE Made Easy.

Basic Electrical Objective Question and Answers from EEE Made Easy & Notebook (Old EEE made Easy)

| Basic Electrical Engineering MCQ’s From Notebook Site (www.notebukofaprofessor.blogspot.com) |

| 1. Basic Electrical Engineering MCQ 1 |

| 2. Current Electricity MCQ |

| 3. Basic Electrical MCQ 2 |

| 4. Basic Electrical Engineering MCQ 3 |

| 5. Basic Electrical Engineering MCQ 4 |

| 6. Basic Electrical Engineering MCQ 5 |

| 7. Basic Electrical Engineering MCQ 6 |

| 8. Basic Electrical Engineering MCQ 7 |

| 9. Basic Electrical Engineering MCQ 8 |

| 10. Basic Electrical Engineering MCQ 9 |

| 11. Basic Electrical Engineering MCQ 10 |

| 12. Basic Electrical Engineering MCQ 11 |

| 13. Basic Electrical Engineering MCQ 2 |

| 14. Basic Electrical Engineering MCQ 14 |