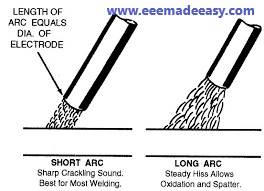

Electric arc length is the straight distance between the electrode tip and the job surface when the arc is formed.

There are three types of arc lengths:

- Medium or normal

- Long

- Short

Download & Install EEE Made Easy App

Medium, normal electric arc

The correct arc length or normal arc length is approximately equal to the diameter of the core wire of the electrode.

This is a stable arc producing steady sharp cracking sound and causing:

- Even burning of the electrode

- Reduction in spatters

- Correct fusion and penetration

- Correct metal deposition

It is used to weld mild steel using a medium coated electrode. It can be used for the final covering run to avoid undercut and excessive convex fillet/ reinforcement.

Long electric arc

If the distance between the tip of the electrode and the base metal is more than the diameter of the core wire it is called a long arc. It makes a humming sound causing:

- unstable electric arc

- oxidation of weld metal

- poor fusion and penetration

- poor control of molten metal

- more spatters, indicating wastage of electrode metal.

It is used in plug and slot welding, for restarting the arc and while withdrawing the electrode at the end of a bead after filling the crater.

Generally long arc is to be avoided as it will give a defective weld.

Short electric arc

If the distance between the tip of the electrode and the base metal is less than the diameter

of the core wire, it is called a short arc.

It makes a popping sound causing:

- the electrode melting fastly and trying to freeze with the job

- higher metal with narrow width bead

- less spatters

- more fusion and penetration.

It is used for root runs to get good root penetration, for positional welding and while using a

heavy coated electrode, low hydrogen, iron, powder and deep penetration electrode

Read more on Electric Welding

- [Set 2]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- [Set 1]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- Electric Welding|Resistance welding Electric Arc Welding

- Resistance Welding|Types of Resistance Welding

- Electric arc welding|Types of Electric Arc welding

- Electric Arc length|Short,Medium, Long Arc

- Open Circuit voltage and Arc voltage|Polarity in arc welding

- Arc Welding Equipments|Arc Welding tools and Accessories

- Arc welding safety|shielded metal arc welding preparation & safety

- Methods of joining metals|Metal Joining Methods

- Types of welds|Weld types

- Applications of Welding|Welding Applications

Books on Welding

Join EEE Made Easy Telegram channel

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus