Resistance Welding:Resistance welding is the process of joining two metals together by the heat produced due to the resistance offered to the flow of electric current at the junctions of two metals.

The heat produced by the resistance to the flow of current is given by:

H= I2 Rt

where I is the current through the electrodes, R is the contact resistance of the interface, and t is the time for which current flows.

Here, the total resistance offered to the flow of current is made up of:

- The resistance of current path in the work.

- The resistance between the contact surfaces of the parts being welded.

- The resistance between electrodes and the surface of parts being welded.

Download & Install EEE Made Easy App

Resistance Welding

Resistance Welding is the process of joining two metals together by the heat produced due to the resistance offered to the flow of electric current at the junctions of two metals.

In this process of welding, the heat developed at the contact area between the pieces to be welded reduces the metal to plastic state or liquid state, then the pieces are pressed under high mechanical pressure to complete the weld.

The electrical voltage input to the welding varies in between 4 and 12 V depending upon area, thickness, composition, etc. and usually power ranges from about 60 to 180 W for each squre mm of area.

Any desired combination of voltage and current can be obtained by means of a suitable transformer in AC; hence, AC is found to be most suitable for the resistance welding.

The magnitude of current is controlled by changing the primary voltage of the welding transformer, which can be done by using an auto-transformer or a tap-changing transformer

Automatic arrangements are provided to switch off the supply after a pre-determined time from applying the pressure, why because the duration of the current flow through the work is very important in the resistance welding.

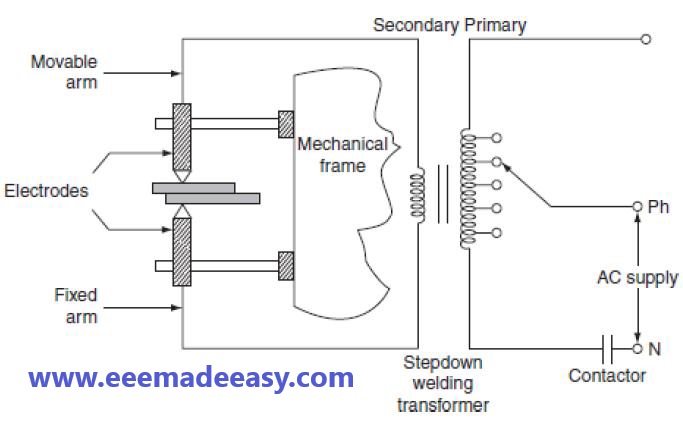

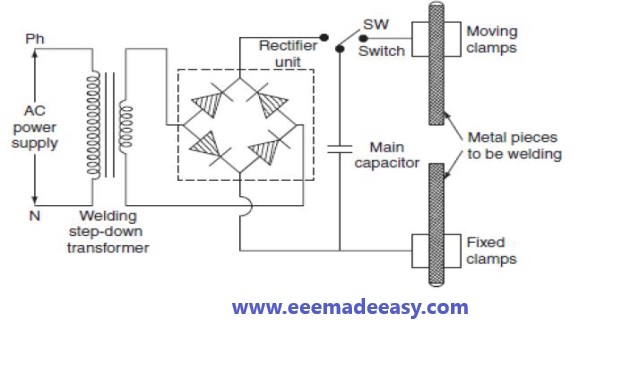

The electrical circuit diagram for the resistance welding is shown in Figure. This method of welding consists of a tap-changing transformer, a clamping device for holding the metal pieces, and some sort of mechanical arrangement for forcing the pieces to form a complete weld.

Advantages of Resistance Welding

o Welding process is rapid and simple.

o Localized heating is possible, if required.

o No need of using filler metal.

o Both similar and dissimilar metals can be welded.

o Comparatively lesser skill is required.

o Maintenance cost is less.

o It can be employed for mass production.

However, the resistance welding has got some drawbacks and they are:

o Initial cost is very high.

o High maintenance cost.

o The work-piece with heavier thickness cannot be welded, since it requires high input current.

Applications of Resistance welding

o It is used by many industries manufacturing products made up of thinner gauge metals.

o It is used for the manufacturing of tubes and smaller structural sections.

Types of resistance welding

Depending upon the method of weld obtained and the type of electrodes used, the resistance welding is classified as:

- Spot welding.

- Seam welding.

- Projection welding.

- Butt welding.

(i) Spot welding

Spot welding means the joining of two metal sheets and fusing them together between copper electrode tips at suitably spaced intervals by means of heavy electric current passed through the electrodes

This type of joint formed by the spot welding provides mechanical strength and not air or water tight, for such welding it is necessary to localize the welding current and to apply sufficient pressure on the sheet to be welded.

The welding current varies widely depending upon the thickness and composition of the plates. It varies from 1,000 to 10,000 A, and voltage between the electrodes is usually less than 2 V. The period of the flow of current varies widely depending upon the thickness of sheets to be joined.

Good weld can be obtained by low currents for longer duration and high currents for shorter duration; longer welding time usually produces stronger weld but it involves high energy expenditure, electrode maintenance, and lot of distortion of workpiece.

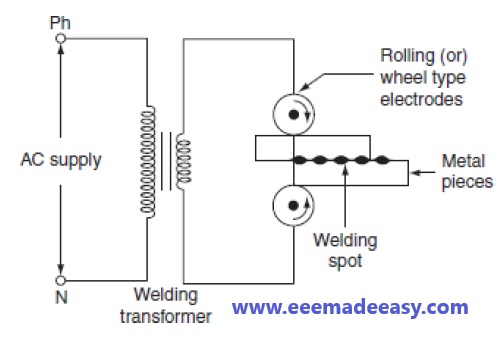

(ii) Seam welding

Seam welding is nothing but the series of continuous spot welding.

If number spots obtained by spot welding are placed very closely that they can overlap, it gives rise to seam welding.

In this welding, continuous spot welds can be formed by using wheel type or roller electrodes instead of tipped electrodes.

When these wheel type electrodes travel over the metal pieces which are under pressure, the current passing between them heats the two metal pieces to the plastic state and results into continuous spot welds.

Seam welding is very important, as it provides leak proof joints. It is usually employed in welding of pressure tanks, transformers, condensers, evaporators, air craft tanks, refrigerators, varnish containers, etc.

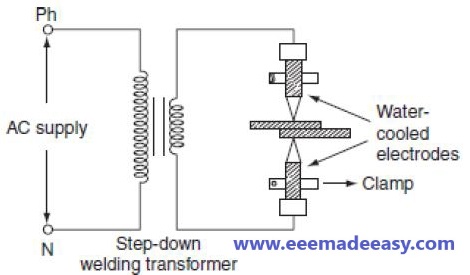

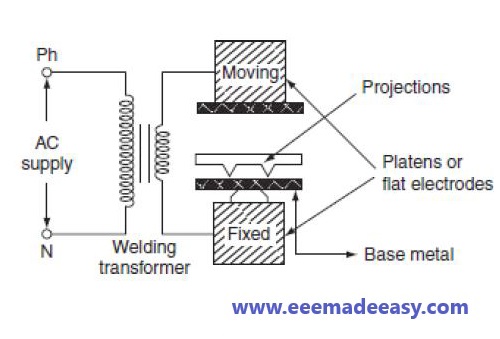

(iii) Projection welding

In the projection welding, both current and pressure are localized to the welding points as in the spot welding.

But the only difference in the projection welding is the high mechanical pressure applied on the metal pieces to be welded, after the formation of weld.

The electrodes used for such welding are flat metal plates known as platens.

One of the two pieces of metal is run through a machine that makes the bumps or projections of required shape and size in the metal.

As current flows through the two metal parts to be welded, which heat up and melt.

These weld points soon reach the plastic state, and the projection touches the metal then force applied by the two flat electrodes forms the complete weld.

The projection welding has the following advantages over the spot welding.

o Simplicity in welding process.

o It is easy to weld some of the parts where the spot welding is not possible.

o It is possible to join several welding points.

o Welds are located automatically by the position of projection.

o As the electrodes used in the projection welding are flat type, the contact area over the projection is sufficient.

This type of welding is usually employed on punched, formed, or stamped parts where the projection automatically exists.

The projection welding is particularly employed for mass production work, i.e., welding of refrigerators, condensers, crossed wire welding, refrigerator racks, grills, etc.

(iv) Butt welding

Butt welding is similar to the spot welding; however, the only difference is, in butt welding, instead of electrodes the metal parts that are to be joined or butted together are connected to the supply.

The three basic types of the butt welding process are:

- Upset butt welding.

- Flash butt welding.

- Percussion butt welding

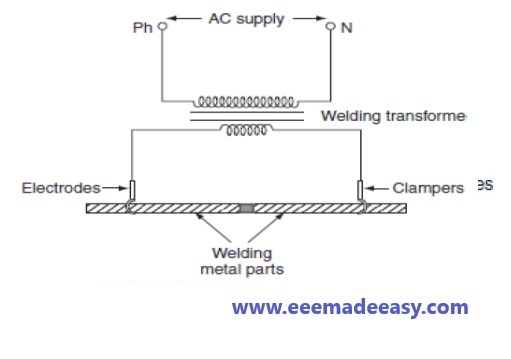

(a) Upset butt welding

In upset welding, the two metal parts to be welded are joined end to end and are connected across the secondary of a welding transformer.

Due to the contact resistance of the metals to be welded, heating effect is generated in this welding.

When current is made to flow through the two electrodes, heat will develop due to the contact resistance of the two pieces and then melts.

By applying high mechanical pressure either manually or by toggle mechanism, the two metal pieces are pressed.

When jaw-type electrodes are used that introduce the high currents without treating any hot spot on the job.

This type of welding is usually employed for welding of rods, pipes, and wires and for joining metal parts end to end.

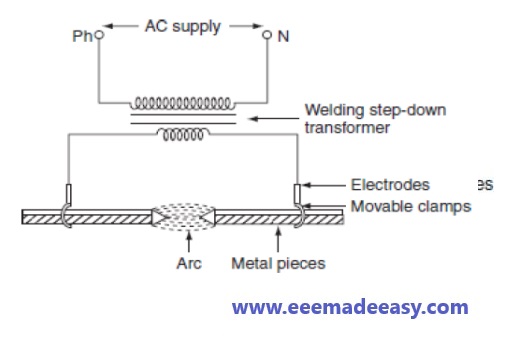

(b) Flash butt welding

Flash butt welding is a combination of resistance, arc, and pressure welding. This method of welding is mainly used in the production welding.

In this method of welding, the two pieces to be welded are brought very nearer to each other under light mechanical pressure.

These two pieces are placed in a conducting movable clamps.

When high current is passed through the two metal pieces and they are separated by some distance, then arc established between them.

This arc or flashing is allowed till the ends of the work-pieces reach melting temperature, the supply will be switched off and the pieces are rapidly brought together under light pressure.

As the pieces are moved together, the fused metal and slag come out of the joint making a good solid joint.

Following are the advantages of the flash butt welding over the upset welding.

- Less requirement of power.

- When the surfaces being joined, it requires only less attention.

•Weld obtained is so clean and pure; due to the foreign metals appearing on the surfaces will burn due to flash or arc.

(c) Percussion welding

It is a form of the flash butt welding, where high current of short duration is employed using stored energy principle. This is a self-timing spot welding method.

Percussion welding arrangement consists of one fixed holder and the other one is movable.

The pieces to be welded are held apart, with the help of two holders, when the movable clamp is released, it moves rapidly carrying the piece to be welded.

There is a sudden discharge of electrical energy, which establishes an arc between the two surfaces and heating them to their melting temperature, when the two pieces are separated by a distance of 1.5 mm apart.

As the pieces come in contact with each other under heavy pressure, the arc is extinguished due to the percussion blow of the two parts and the force between them affects the weld.

The percussion welding can be obtained in two methods; one is capacitor energy storage system and the other is magnetic energy storage system.

The capacitor ‘C’ is charged to about 3,000 V from a controlled rectifier. The capacitor is connected to the primary of welding transformer through the switch and will discharge.

This discharge will produce high transient current in the secondary to join the two metal pieces. Percussion welding is difficult to obtain uniform flashing of the metal part areas of the cross-section grater than 3 sq. cm.

Advantage of this welding is so fast, extremely shallow of heating is obtained with a span of about 0.1 sec.

It can be used for welding a large number of dissimilar metals.

Applications of percussion welding

•It is useful for welding satellite tips to tools, sliver contact tips to copper, cast iron to steel, etc.

•Commonly used for electrical contacts.

•The metals such as copper alloys, aluminum alloys, and nickel alloys are percussion welded.

Join EEE Made Easy Telegram channel

Read more on Electric Welding

- [Set 2]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- [Set 1]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- Electric Welding|Resistance welding Electric Arc Welding

- Resistance Welding|Types of Resistance Welding

- Electric arc welding|Types of Electric Arc welding

- Electric Arc length|Short,Medium, Long Arc

- Open Circuit voltage and Arc voltage|Polarity in arc welding

- Arc Welding Equipments|Arc Welding tools and Accessories

- Arc welding safety|shielded metal arc welding preparation & safety

- Methods of joining metals|Metal Joining Methods

- Types of welds|Weld types

- Applications of Welding|Welding Applications

Books on Welding

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus