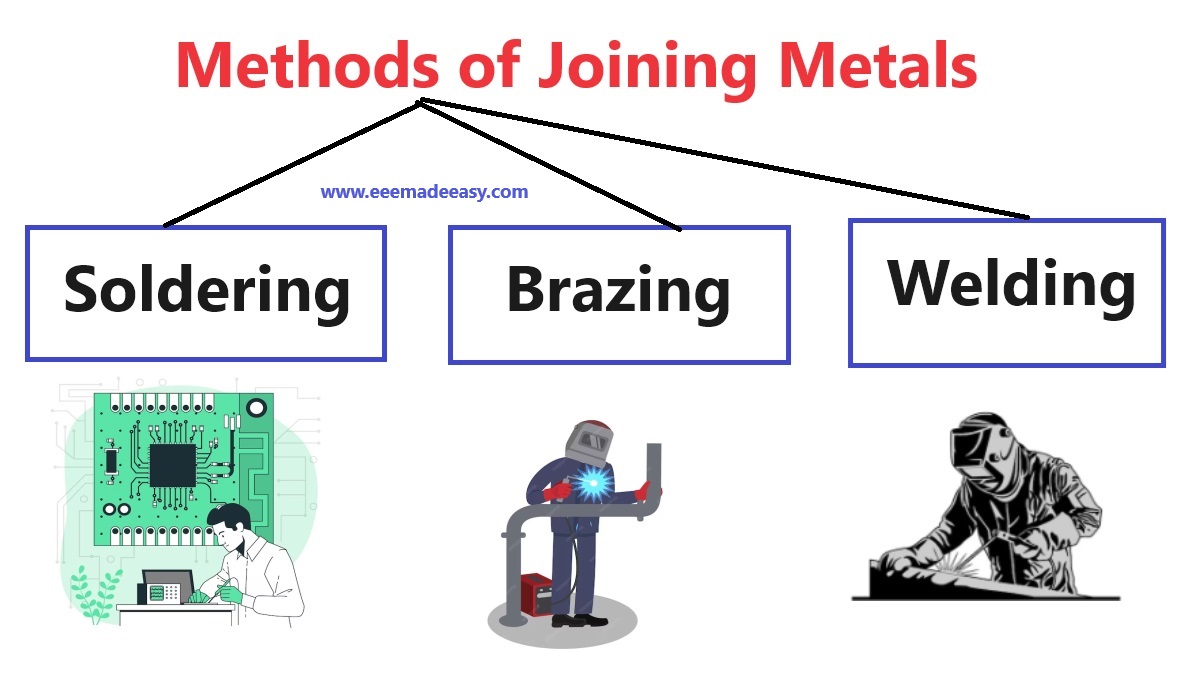

Methods of joining metals : The three main methods of joining metals are Soldering, Brazing,and welding. In this post, we will discuss each of these metal joining methods.

The art of joining metals is about 3000 years old. The origin of welding is probably to be traced to the shaping of metals. In industry every worker is working for changing the shape of metals by different methods and machines. Welding is a metal joining method.

Join EEE Made Easy Telegram channel

The following methods are used for joining metals

(i) Soldering

This joint is made on thin metals using solder as a joining medium. The melting point of solder is less than the metals to be joined.

The joint can be opened by heating upto the solder melting temperature (below 400°C).

(ii) Brazing

The joint is similar to soldering but has more strength. The joining medium used is brass, which has a higher melting temperature than solder. The joint can also be opened by heating upto the melting point of brass (850-950°C).

(iii) Welding

A metal joining method in which the joining edges are heated and fused together with or without filler metal to form a permanent (homogeneous) bond is known as welding.

Or in other words, “Welding is a process of joining two or more pieces of the same or dissimilar materials to achieve complete coalescence.

This is the only method of developing monolithic structures and it is often accomplished by the use of heat and/or pressure.

Joining methods like riveting, assembling with bolt, seaming, soldering and brazing all result in temporary joints.

Welding is the only method to join metals permanently.

The temporary joints can be separated if:

- the head of the rivet is cut

- nut of the bolt is unscrewed

- hook of the seam is opened

- more heat is given than that required for soldering and brazing.

Welded joints cannot be separated like soldering and brazing because it is made

homogeneous by heating and fusing the joining edges together.

Join EEE Made Easy Whatsapp Channel

Advantages of Welding

Welding is superior to other metal joining methods because it:

- is a permanent pressure tight joint

- occupies less space

- gives more economy of material

- has less weight

- withstands high temperature and pressure equal to joined material

- can be done quickly

- gives no colour change to joints.

It is the strongest joint and any type of metal of any thickness can be joined.

Different Methodsof Welding

Welding is a method of joining metals permanently. It is an ancient method, about

1500 years old.

The method used in ancient days was forge or blacksmith welding.

One of the methods of classifying welded joints is the method used to effect the joint

between metal pieces. Accordingly the methods are:

- fusion method without pressure/ with pressure

- non-fusion method

Fusion welding without pressure

A method of welding in which similar and dissimilar metals are joined together by melting and fusion their joining edges with or without the addition of filler metal but without the application of any kind of pressure is known as fusion welding without pressure.

The joint made is permanent. The common heating sources are:

- arc welding

- gas welding

- chemical reaction (thermit welding)

Pressure welding

This is a method of welding in which similar metals are joined together by heating them to plastic or partially molten state and then joined by pressing or hammering without the use of filler metal. This is fusion method of joining with pressure.

Heat source may be blacksmith forge (forge welding) or electric resistance (resistance

welding) or friction.

Non-fusion welding

This is a method in which similar or dissimilar metals are joined together without melting the edges of the base metal by using a low melting point filler rod but without the application of pressure.

Download & Install EEE Made Easy App

Welding process classification based on Heat source

According to the sources of heat, welding processes can be broadly classified as:

- Electric welding processes (heat source is electricity)

- Gas welding processes (heat source is gas flame)

- Other welding processes (heat source is neither electricity nor gas flame)

Electric welding

Electric welding processes can be classified as:

- Electric arc welding

- Electric resistance welding

- Laser welding

- Electron beam welding

- Induction welding

Electric arc welding can be further classified as:

- Metallic arc welding

- Carbon arc welding

- Atomic hydrogen arc welding

- Inert gas arc welding/ TIG welding

- CO2 gas arc welding

- Flux cored arc welding

- Submerged arc welding

- Electro-slag welding

- Plasma arc welding

Electric resistance welding can be further classified as:

- Spot welding

- Seam welding

- Butt welding

- Flash butt welding

- Projection welding

Gas welding processes can be classified as:

- Oxy-acetylene gas welding

- Oxy-hydrogen gas welding

- Oxy-coal gas welding

- Oxy-liquefied petroleum gas welding

- Air acetylene gas welding

The other welding processes are:

- Thermit welding

- Forge welding

- Friction welding

- Ultrasonic welding

- Explosive welding

- Cold pressure welding

- Plastic welding

Read more on Electric Welding

- [Set 2]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- [Set 1]MCQ’s on Electrical Welding|Electrical Welding MCQ Questions and Answers|KSEB Sub Engineer

- Electric Welding|Resistance welding Electric Arc Welding

- Resistance Welding|Types of Resistance Welding

- Electric arc welding|Types of Electric Arc welding

- Electric Arc length|Short,Medium, Long Arc

- Open Circuit voltage and Arc voltage|Polarity in arc welding

- Arc Welding Equipments|Arc Welding tools and Accessories

- Arc welding safety|shielded metal arc welding preparation & safety

- Methods of joining metals|Metal Joining Methods

- Types of welds|Weld types

- Applications of Welding|Welding Applications

Books on Welding

Join EEE Made Easy Whatsapp Channel

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus