LVDT stands for Linear Variable Differential Transformer. LVDT is a passive inductive transformer which requires an external source of power. LVDT is used to measure linear displacement.

Read also: Transducer Types, Parts, Working, Applications with Examples

What is LVDT?

A Linear Variable Differential Transformer (LVDT) is a common type of position sensor that converts the linear position or motion of a measured object to a proportional electrical output that can be read by operators and control systems.

LVDTs are most frequently used where measuring ranges vary from ±0.010 inches (±0.254 mm) to ±10 inches (±254 mm).

LVDTs can be designed for temperatures from cryogenic ranges -238°F (-150°C) to as high as 1000°F (537°C).

The LVDT features frictionless operation, is very rugged in harsh environments, possesses

excellent accuracy and repeatability, and has a nearinfinite expected service life.

LVDT Parts

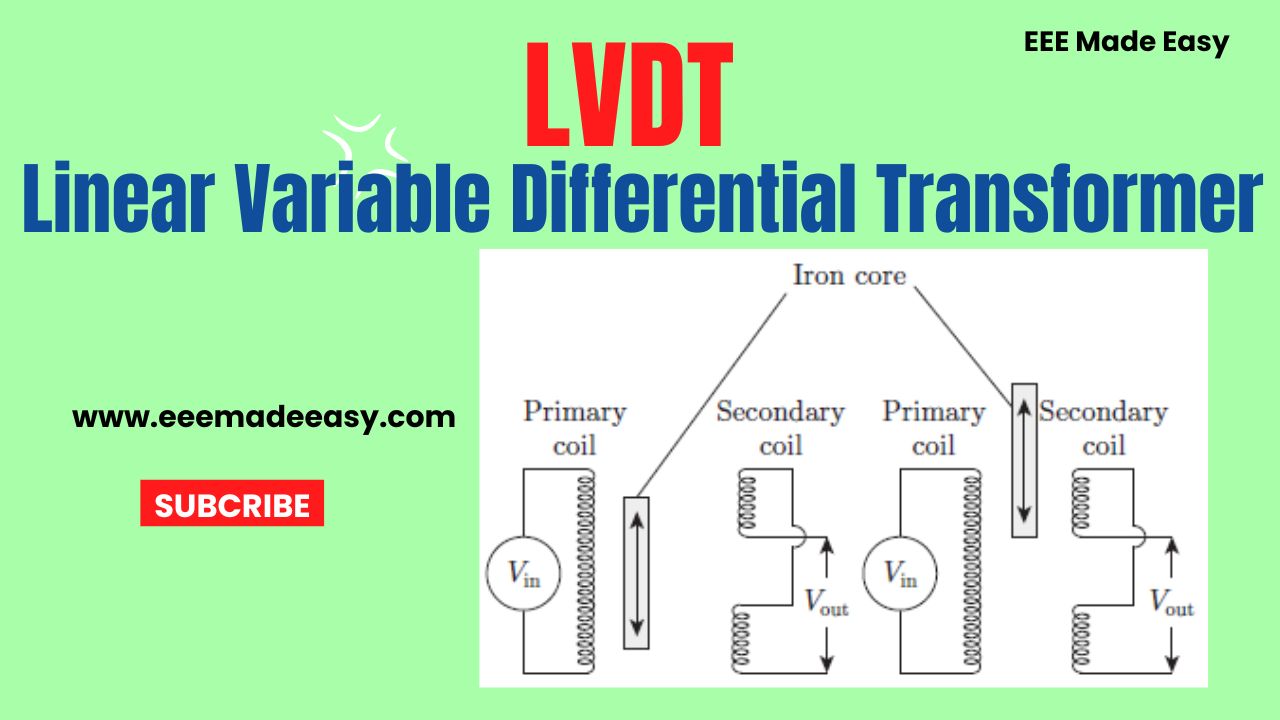

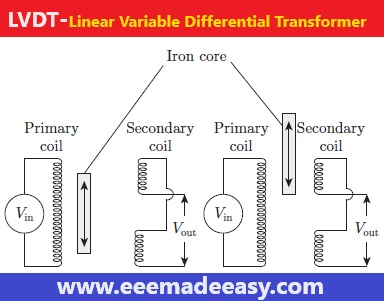

It consists of a primary winding and two secondary windings. These windings are wound over a hollow tube and the primary winding is kept between the two secondaries.

An LVDT has two components: a fixed housing containing the single primary winding with two

secondary windings S1 and S2, and a movable core constructed of ferromagnetic material and

mechanically linked to the measured object.

There is no physical contact between the housing and the core.

The single primary coil is centered in the housing and energized with an AC signal.

Magnetically coupled by the core, a voltage is induced in each of two symmetrical secondary windings connected in a series-opposing circuit.

The effective voltage and LVDT output is the difference between each secondary.

working of LVDT

Figure shows the schematic and working of LVDT.

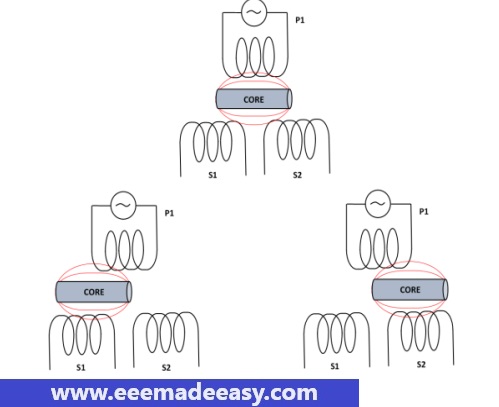

A movable iron core slides within the hollow tube and affects the magnetic coupling between the coils.

When the iron core is centrally placed, the voltage induced is equal in the two secondaries. When the core is moved in direction of the centre, voltage is increased in one of the windings while voltage in the other gets decreased.

When the core moves away from the center of the LVDT, known as the null point, the signal from the primary will be coupled to one secondary more than the other.

In above Figure, as the core moves over S1, the voltage output of S1 increases. As the core moves over S2, the output of S2 increases.

The value of (S1 – S2) and (S2 – S1) becomes a linear function of the core position as it moves toward S1 and S2, respectively.

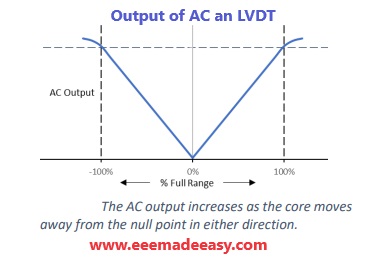

The typical output of AC an LVDT is shown in Figure above. As the core moves away from the null point in either direction within the LVDT range, the voltage outputs (S1 – S2) and (S2 – S1) increase proportionally.

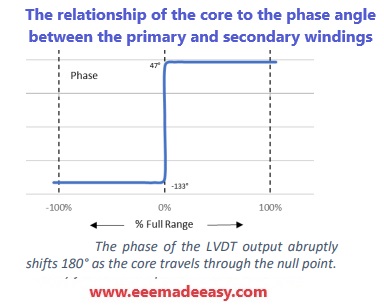

The above Figure shows the relationship of the core to the phase angle between the primary and secondary windings.

As the core travels across the null point the phase of the output signal abruptly shifts by 180°

as shown in Figure, allowing a user or signal conditioning electronics to determine which side of null the core is on.

Being an inductive transformer, the LVDT requires an AC excitation voltage across the primary and produces an AC output across the secondaries.

In modern LVDTs, excitation signal requirements are around 3 Vrms and frequencies ranging from 1kHz to 10 kHz.

Support electronics and signal conditioners supply the excitation signal and measure output.

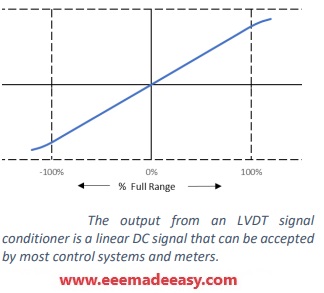

Signal conditioners demodulate the low-amplitude AC output and produce DC voltage, current, or digital output that can be measured by most meters and control systems.

In addition to an external component, signal conditioners can also be built into the LVDT.

Often referred to as DC LVDTs, the user can supply a DC input, and measure a DC output corresponding to the core position.

DC LVDTs offer many of the benefits of LVDT technology with the convenience of supplying and reading a DC signal.

Advantages of LVDT

- It can produce high output voltage with relatively low change in core position.

- It is also less costly, solid and robust in construction

Disadvantages of LVDT

- LVDT is sensitive to stray magnetic fields so it always requires a setupto protect them from stray magnetic fields.

- is affected by vibrations and temperature

Join EEE Made Easy Whatsapp Channel

- [PDF]Electrical Measurements Measuring Instruments Study Notes PDF|EMMI Notes EEE Made Easy

- MCQ on Electrical Instruments

- Types of Errors in Instruments| Instrument Errors

- MCQ’s on Electrical Measuring Instruments|Instruments Objective Questions

- Electrical measuring instruments|Types of Measuring Instruments

- Static characteristics of instruments

- Types of measuring instruments- www.eeemadeeasy.com

- Moving Iron Instruments

- Instruments- Basics

- PMMC Instruments

- Types of instruments

- Essentials of Indicating instruments

- MCQ’s on Galvanometer|Galavnometer Questions & Answers

- MCQs on potentiometer|potentiometer Questions and answers

- TOD Meter or Time of Day Meter

- Light meters or illumination meter|Lux meter

- VU and decibel meters

- Multimeter- Principle and operation

- Digital readout meters-principle and operation

- Watt-hour meters- principle and operation

- Wattmeter -principle and working

- FET and vacuum-tube voltmeters

- Ohmmeter- basic principle and working

- Ammeters|Current Measurement

- Voltmeter- Principle and operation

- The household energy meter is

- Q Meter

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus