What is FHP motor?

An FHP motor or fractional horsepower motor is an AC or DC motor that produces less than one horsepower with an output rating of 746 watts or less.

The low power level of fractional horsepower motors makes them ideal for small electronics and simple consumer devices.

When they are part of a large mechanism, such as a car, they continue running even if the power to the device stops.

What are the different types of FHP motors?

- Reluctance Motor

- Stepper Motor

- Servo Motor

- shaded pole

- Capcitor Start- Capacitor run

- Universal Motor

Small electric motors use 745.7 watts of power.

They are durable and reliable and have four basic parts: two battery leads, a cylindrical enclosure, an axle, and a nylon end cap.

½ HP motors

½ HP motors are FHP motor types that run on about 373 watts of power, which is half of one horsepower.

¼ HP motor

¼ HP motors are FHP motors that run on one quarter of a horsepower, which is approximately 186 watts.

Variable speed FHP motors

Variable speed FHP motors can direct the speed of the motor to increase or decrease as desired. The low horsepower makes the speed and motion easier to control since control in an FHP motor is so precise.

Variable speed FHP motors

Electric powered fractional motors are built with a rotor (AC motor rotor or DC motor rotor), axle, coil, field magnet, and enclosure. To help conduct electrical currents, some FHP electric motors also have internal brushes.

Brushless FHP motor

Brushless FHP motors are costlier because they require an external power supply to transfer their current.

Fuel-powered fractional horsepower motors

Fuel-powered fractional horsepower motors use exhaust valves and a fuel chamber to generate power instead of a coil and magnet. FHP fuel-powered motors, also called internal combustion engines, can be fueled using gasoline or diesel depending on the design.

Permanent magnet motors

Permanent magnet motors are FHP motors powered by permanent magnets (PMs) located in their rotor assemblies. There, the assembly stays in line with the stator magnetic field as it rotates.

PMs create motors with more power, higher torque (even when running at a low speed), higher torque efficiency, and no slip. The only disadvantage of permanent magnet motors is their cost; because manufacturers often make the with rare earth magnets, they can be quite expensive.

FHP induction motors

FHP induction motors contain not permanent magnets, but only electromagnets. Induction motors employ a coil wrapped around a stator in order to modulate electrical current.

FHP single-phase motors

FHP single-phase motors are popular as inexpensive, efficient, and trustworthy motors. They run using a single-phase AC electric power. In other words, they get all of their voltages in unison from one source.

FHP gearmotors

FHP gearmotors reduce motor speeds using a combination of the motor and a gear head.

Sub-fractional motors/ micro motors

Sub-fractional motors, also known as micro motors, are extremely small fractional horsepower motors. Typically, they are found in items like electric toothbrushes or remote controlled toys.

Shaded-Pole Motors

Shaded-pole motors are used for applications such as fans and blowers where there is a low horsepower requirement.

Their values range from as low as 0.0007 HP to 1/4 HP. Most are manufactured in the range of

1/100 to 1/20 HP.

Advantages of Shaded-pole motors

These motors have an advantage in that they are very simple to construct, reliable, rugged, and have a low cost.

They do not require auxiliary parts such as capacitors, brushes, commutators, or movable switches.

Maintenance on them is minimal and simple.

Under locked-rotor conditions these motors do not draw much more line current than when operating normally.

This provides automatic circuit protection, and the motor will not overheat and destroy itself.

Disadvantages of Shaded-pole motors

The shaded-pole motor has a very low starting torque and very low efficiency.

Maximum efficiency for the 1/20 horsepower motor is only about 35%. For the smaller motors it is as low as 5%.

The power factor is also poor.

Because these motors use such small power, however, the advantages far outweigh the disadvantages when the application is appropriate.

Principles of Operation of Shaded-pole motors

Shaded-pole motors operate on the induction principle as the single-phase motors.

They obtain their name from the method used to produce a rotating magnetic field to provide starting torque.

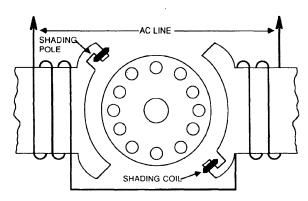

The pole pieces have a slot cut in them on which is wound the shaded pole coil. The shading coils are normally a short-circuit single turn of heavy gauge copper wire.

The wire is formed fitted on the shaded-pole which is a notch cut into the main stator pole.

The shaded-pole coil is held in place with pins or wedges.

All shaded pole motors use the squirrel cage rotor.

Reluctance Motor

A reluctance motor works like a single-phase induction motor with rings at both ends of the motor.

The central components of a reluctance fractional horsepower motor are its stator and rotor, which are separated by an air gap.

They work with a precision rotating magnetic field by matching the speed of the rotor using the magnetic field of the stator.

The unique construction of a reluctance fractional horsepower motor makes it possible for them to deliver high-density power at a very low cost.

The motor concept is based on the principle that when a magnetic material is in a magnetic field, it is brought into line in a less reluctance way.

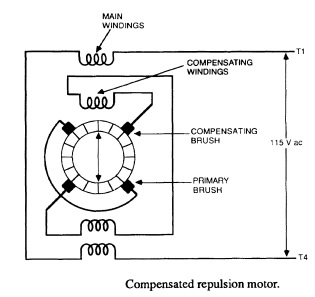

Repulsion Motor

Before the general acceptance of the capacitor-start motor, the repulsion-type motor was used extensively to drive high-inertia loads where only single-phase power was available.

This motor develops more starting torque per ampere than any other type.

It requires about 35% of the starting current as that of the capacitor-start motor to deliver the same amount of torque.

Repulsion motors have horsepower ratings from 1/8 to 15.

There are three general classifications of repulsion type motors. These are

- Repulsion-start, induction-run

- Repulsion

- Repulsion-induction

The repulsion motor starts and runs on the repulsion theory.

Universal Motors

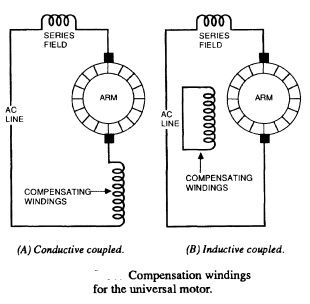

Universal motors get their name because they will operate either on DC or AC up to 60 Hz. Their performance will be essentially the same when operated on DC or at 60 Hz.

Applications of Universal Motor

universal motors are designed for special applications.

They are commonly used in common electrical hand tools such as power saws, portable drills, routers, and joiners.

They are also used for vacuum cleaners, mixers, and a host of household appliances that require an electric motor.

Theory of operation of Universal motor

The theory of operation of the universal motor is the same as that of the DC motor. Direct current motors do not operate well on AC because of poor efficiency, low power factor, and arcing at the brushes.

The design of the universal motor reduces these deficiencies to an acceptable level.

Shunt-type designs are not used for universal motors because of the high reactance present when the motor is operated on AC.

This would reduce the current flow through the shunt field and weaken the magnetic effect below the required torque to start the motor.

Which is not a fractional horsepower motor?

Usually, the Motors which has power less than one Horse Power is called a FHP Motors.

Fractional Horsepower Motors

A fractional-horsepower motor (FHP) is an electric motor with a rated output power of less than one horsepower (745.7 W) (the term ‘fractional’ indicates less than one unit).

Two types of fractional horsepower motors are stepper and servo motors which allow for a precise input level.

Applications of FHP Motors

Fractional horsepower motors are widely used in robotics due to their precision and control The

Fractional-horsepower motors are used across a wide range of industries and applications for a variety of motion and compression needs.

For driving auxiliary applications such as electric windows, windshield wipers, powered seats, wing mirrors, central locking systems, roof openers, and trunk openers.

.

For example, FHP motors are being used to drive pumps and compressors in refrigerators, coffee machines, and washing machines, and they provide suction in vacuum cleaners and a variety of other switching and motion tasks across the ever-increasing variety of domestic products.

Other applications include: pumps & compressors, medical devices, portable tools, office machinery, and HVAC.

servo motor

A servomotor (or servo motor) is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration.

It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with servomotors.

Servomotors are not a specific class of motor, although the term servomotor is often used to refer to a motor suitable for use in a closed-loop control system.

Servomotors are used in applications such as robotics, CNC machinery, and automated manufacturing.

stepper motor

A stepper motor, also known as a step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps.

The motor’s position can be commanded to move and hold at one of these steps without any position sensor for feedback (an open-loop controller), as long as the motor is correctly sized to the application in respect to torque and speed.

Switched reluctance motors are very large stepping motors with a reduced pole count, and generally are closed-loop commutated.

There are three main types of stepper motors:

- Permanent magnet stepper

- Variable reluctance stepper

- Hybrid synchronous stepper

Electrical Machines Best Books

| Sl no. | Book Title | Author | Buy Link |

|---|---|---|---|

| 1 | Textbook Of Electrical Technology : Ac And Dc Machines (volume – 2) | B L Theraja, AK Theraja | check price |

| 2 | Theory & Performance of Electrical Machines | J.B. Gupta | check price |

| 3 | Electrical Machines | by V.K Mehta, Rohit Mehta | check price |

| 4 | Electric Machines | PS Bimbhra | check price |

| 5 | Electrical Machines | S.K. Bhattacharya | check price |