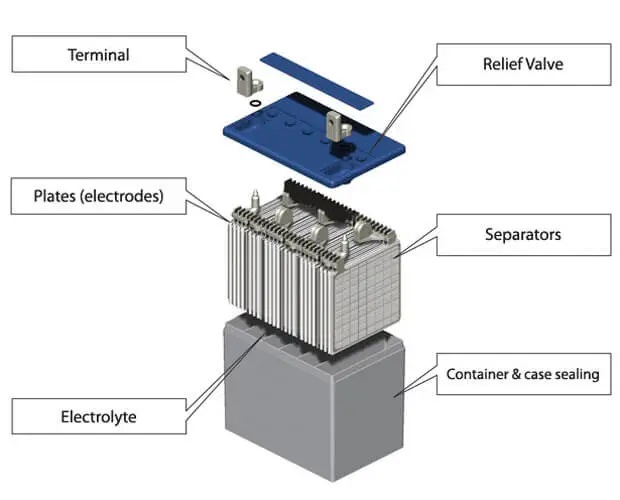

VRLA Battery : A VRLA batttery (Valve Regulated Lead Acid battery) also known as Sealed Lead Acid (SLA) battery, is a type of lead acid battery characterized by a limited amount of electrolyte absorbed in a plate separator or formed into a gel. The oxygen recombination is facilitated within the cell by the proportioning of the negative and positive plates and the presence of a relief valve that retains the battery contents independent of the position of the cells.

There are two types of VRLA batteries, Absorbent Glass Mat (AGM) and gel cell batteries.

Gel cells add silica dust to the electrolyte, forming a thick putty like gel. AGM (absorbent glass mat) batteries feature fiberglass mesh between the battery plates which serves to contain the electrolyte and separate the plates.

Both types of VRLA batteries offer advantages and disadvantages compared to flooded vented lead acid (VLA) batteries or each other.

VALVE REGULATED LEAD ACID BATTERIES

The conventional lead acid batteries used in signalling circuits as a source of D.C supply suffers from number of maladies which enclosed regular topping-up a separate storage arrangement which amount to increases maintenance and reduced reliability.

The new improved valve regulated lead acid (VRLA) battery over come much of these earlier deficiencies.

As the name suggests, these are sealed valve regulated batteries with absorptive glass mat (AGM) separator to permit the oxygen evolved from the positive plate to the fuse to the negative plate.

Join EEE Made Easy Whatsapp Channel

The microporous glass separator as used in VRLA is not completely saturated with electrolyte and the wide space thus available allows an unimpeded access of oxygen to the negative

plate.

The oxygen gas gets reduced at the negative plate surface, thereby effectively suppressing the evolution of hydrogen.

Consequently, Power stacks cells do not loose any water under normal operation and therefore, no topping- up is required.

Valve regulated lead acid battery (VRLA) use a patented MFX alloy for the positive grid, which exhibits excellent deep discharge performance.

In addition , it has a universally acclaimed maintenance free lead calcium alloy for the negative grid.

The power stack cells so formed require very little maintenance and have longer life duration.

VRLA Battery features and advantages

VRLA batteries are based on “Starved electrolyte design and Oxygen recombination principle.”

The important functional features and advantages are as under.

- No periodic topping up of electrolyte is required.

- No spillage of electrolyte as it is sealed.

- These cells are supplied in fully charged condition, therefore, no initial charging is required.

- These have very low self-discharge the order of 20% to 25% of conventional lead acid batteries.

- These can be used as either vertically or horizontally. They are available in stackable steel trays capable of being mounted one over the other. Therefore, they occupy very less space.

- They do not emit any toxic, corrosive acid fumes, hence can be installed in the equipment room itself, saving the battery room.

- They are lighter in weight by about 25% when compared to conventional lead acid batteries.

- They have 30% to 40% longer life than the conventional lead acid batteries.

Constructional features of VRLA Battery

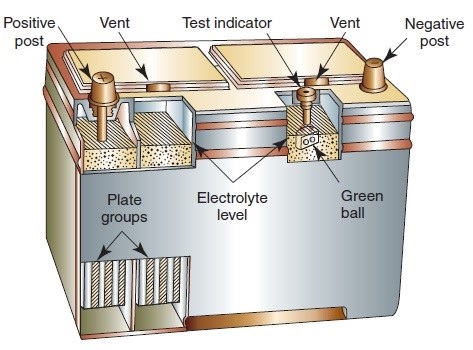

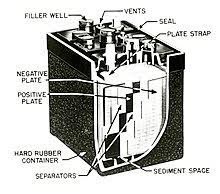

The main components of lead acid cell are as under.

Positive plates

Positive plate consists of a number of flat tubes, containing patented MFX alloy.

Negative plate

It is made of lead-calcium alloy.

Container

Container of battery is made of suitable flame retardant Polypropylene Copolymer plastic (PPCP) with high insulating strength to resist acids and low permeability to water vapors.

The container is enclosed in epoxy coated steel trays. The steel tray is so designed as to permit both vertical and horizontal stacking of cells.

Electrolyte

The sulfuric acid and water used as electrolyte for the battery confirming to IS

266-77 and IS 1069-64 respectively.

Separators

Separators consists of either of microporous glass mat or synthetic material

having high acid absorption capabilities and also resistant to sulfuric acid.

Safety Vent Plug

The plug is explosion resistant and is of pressure regulating type. Safety Vent

Plug does not permit ingress of air into the unit.

Terminals

The terminals of the battery generally comprise of solid copper core.

Nuts and Bolts

Nuts and bolts used to connect the cells are made of copper, brass or stainless

steel. These are effectively lead coated in order to prevent corrosion.

Recombination Principles of VRLA Batteries

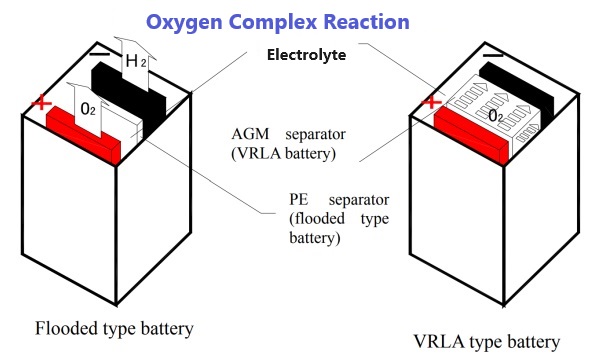

Under typical charging conditions, oxygen at the positive plate occurs before the evolution of hydrogen at the negative plate.

This feature is utilized in the design of VRLA batteries.

The oxygen gas evolved at the positive plate instead of bubbling upwards is transported in the gaseous phase through the separator medium to the negative plate.

The separator which is of highly absorbent glass mat type has very high porosity designed to have pore volume in excess of the electrolyte volume (starved electrolyte design), due to which the Oxygen gas finds an unimpeded path to the negative plate.

Reaction reduces the Oxygen gas with the spongy lead at the negative plate turning a part of it into a partially discharged condition, there by effectively suppressing the hydrogen gas evolution at the negative plate.

This is what is known as the Oxygen recombination principles.

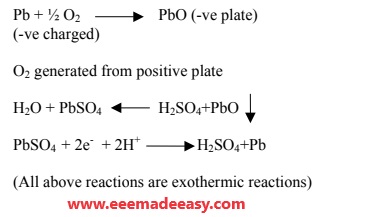

Principle of VRLA Battery

The VRLA battery is designed so that the negative plate does not have to be fully charged even when the positive plate is charged fully.

Here no H2 gas is generated from the negative plate though O2 gas is generated from the over

charged positive plate.

The O2 gas so generated from the positive plate reacts with charged spongy lead (Pb) of the negative plate and forms Lead Monoxide (PbO).

The Lead Monoxide in turns reacts with Sulfuric Acid (H2SO4) in the electrolyte and forms Lead Sulphate (PbSO4), thus allowing the negative plate to be discharged.

In other words, O2 from the positive plate is absorbed by the negative plate without being expelled to the outside.

Since the negative plate develops discharging with the help of O2 evolved at positive plate during charging, the negative plate as a result never generates H2.

This completely prevents the loss of water.

The over all reactions may be expressed as follows.

Manufacturers supply duly charged batteries and thus no initial charging is required and therefore these are ready to use.

Such a battery requires no topping up and maintenance except for periodic cleaning of the terminals.

The battery has self sealing vent plug, which normally does not open out in service.

Under normal conditions they emit no corrosive fumes or gases.

Receiving the shipment of VRLA Batteries

- Check the packing boxes carefully for any damage during transportation and handling.

- Check the number of packages as per packing slip.

- During unloading, care must be taken to prevent dropping the packing boxes on the ground since this can cause damage to the batteries.

- Protect the packing cases from sunlight or other sources of heat exposure even for short periods as it can cause permanent damage to the battery.

- Protect the packing cases from rain or other sources of water.

VRLA Battery Price

VRLA Battery price ranges from 500 Rs to 5600 Rs depending on the brand, features and quality. Some Examples are given below.

Do’s and Don’ts for VRLA Battery

Do’s VRLA Battery

- Unload the batteries carefully and place them upright on the floor in the single tier.

- Store the batteries in cool and dry location.

- Charge the batteries every six months for the storage period.

- Unpack the batteries as per the unpacking instructions.

- Install the batteries in cool and dry location.

- Monitor the charge and float voltages of the power plant at monthly intervals and adjust, if required.

- Check the tightness of all electrical connections at monthly intervals.

- Always use a spring washer wherever bolt connections are provided

- After a discharge, re-charge the batteries immediately.

- Check the compatibility of power plant and replace with the modified one if required.

- Maintain service record as per the instructions.

Don’ts VRLA Battery

- Do not exceed the charging voltage above 2.30V maximum per cell.

- Do not open the safety valve for adding water or acid.

- Do not attempt to dismantle the battery.

- Do not boost charge the batteries for more than 12 hours.

- Do not mix ordinary conventional, low maintenance batteries with maintenance free VRLA batteries.

- Do not expose the packed batteries to rain and sunlight.

- Do not install the batteries in rooms with varying temperature pockets due to sun light or ventilation ducts.

- Do not keep the cells in idle condition for more than the specified storage

- period without charging the batteries.

- Do not short-circuit the battery or cells during assembly.

- Do not over tighten the terminals.

- Do not charge the batteries in sealed cubicles.

- Do not mix batteries of different types or makes.

- Do not make tap connections.

- Do not tamper with the cell vents.

VRLA Battery FAQ’s

what is vrla battery?

Valve Regulated Lead Acid -VRLA Batteries are low-maintenance lead acid rechargeable batteries

what is vrla agm battery?

Absorbed Glass Mat (AGM) is a form of SLA/VRLA

what is difference between vrla and smf battery?

VRLA batteries use a valve to regulate gas buildup. SMF batteries are sealed and recombined gases internally

what is smf vrla battery?

SMF batteries are sealed and recombined gases internally

vrla battery full form?

Valve Regulated Lead Acid Battery is the full form of VRLA Battery

vrla battery means ?

Valve Regulated Lead Acid

VRLA full form?

Valve Regulated Lead Acid

What is meant by VRLA battery?

Valve Regulated Lead acid battery uses Valve regulation for gases, uses less water.

Which is better VRLA or lead-acid battery?

V in VRLA stands for valve regulated, its an added advantage compared to LA or Lead acid battery

Is VRLA and AGM the same?

Yes, AGM is a special type of VRLA Batteries. AGM- Absorbed Glass Mat

What is difference between VRLA and SMF battery?

VRLA batteries use a valve to regulate gas buildup. SMF batteries are sealed and recombined gases internally

What is SLA battery?

Sealed Lead Acid battery is another nae for VRLA Battey

Read Also

- Battery Capacity Tester|Battery Tester

- MCQ’s on Cells and Batteries|Cells and batteries Objective Questions

- Cells and batteries|

Join EEE Made Easy Whatsapp Channel

Join EEE Made Easy Telegram channel

Download & Install EEE Made Easy App

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus