Types of electrical wiring are Cleat wiring, Wooden or batten wiring, Conduit wiring, Casing and Capping, trunking and cts-trs wiring.

Electrical Wiring

A process of connecting various accessories for distribution of electrical energy from supplier’s meterboard to home appliances such as lamps, fans and other domestic appliances is known as Electrical Wiring.

Types of Electrical wiring

There are following types of electrical wiring:

- Cleat wiring or Temporary wiring

- Wooden or Batten wiring

- Casing and Capping

- Conduit Wiring

- Trunking Wiring

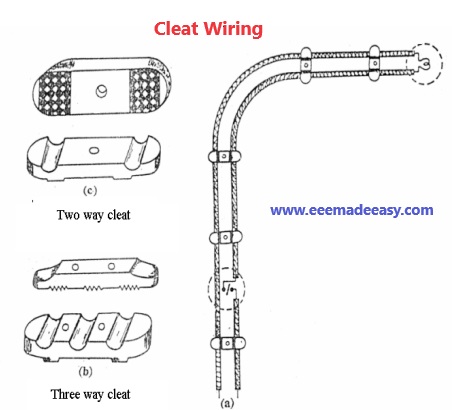

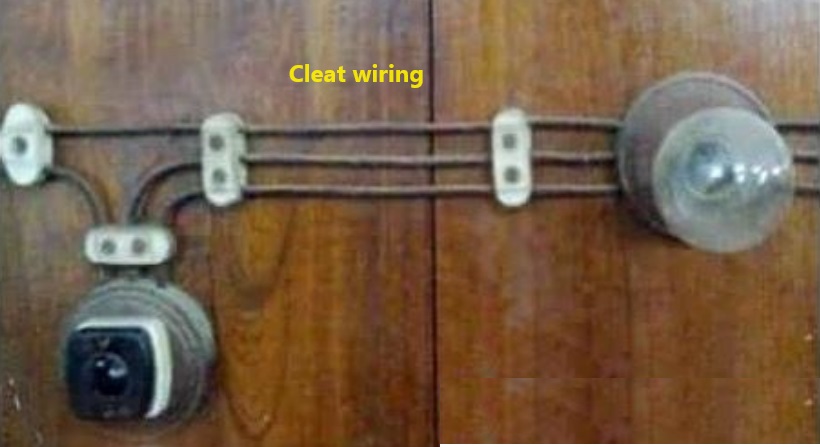

Cleat Wiring or Temporary Wiring

It is a temporary wiring used for function and construction work.

Wooden and plastic cleats used for this purpose and distance between the two cleats lies between 4 to 6 feet.

Download & Install EEE Made Easy App

Join EEE Made Easy Telegram channel

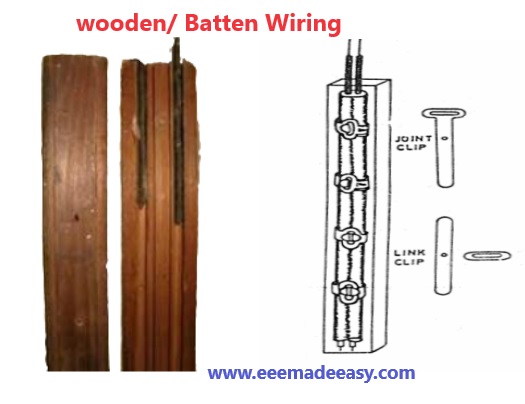

Wooden or Batten Wiring

Wooden pieces and steel clips are used for this purpose Distance between two clips will be 4 to 6 inches.

Steel clips is fixed with the help of nail and then lay out the wire on the wooden piece and then fixed them with steel clips.

Advantages of Wooden/Batten wiring

- Cheap wiring.

- Installation is easy.

- Extension is possible.

- Easy to locate the fault as the wires are open.

Disadvantages of Wooden/Batten wiring

- In case of short circuit wood can easily catch the fire.

- Unsafe from mechanical damages

- Unsafe from water.

- Life span is short i.e. about 10 to 15 years.

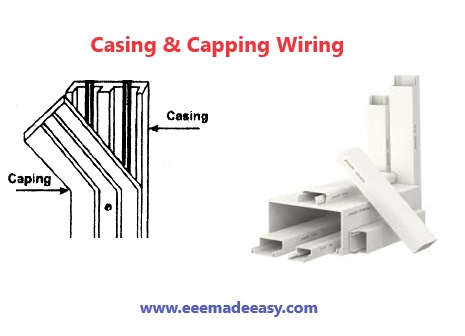

Casing and Capping Wiring

It consists of two parts lower one is called casing and the upper part for covering is known as capping. Casing is fixed with the help of rawal plug.

Then lay out the wires and cables in the casing and finally covered with capping.

Sizes of Casing and Capping

Following size of casing and capping are easily available.

- 16x16mm

- 16x25mm

- 16x38mm

- 38x40mm

- 40x40mm

- 40x60mm

- 60x80mm

- 80x80mm

Advantages of casing and capping wiring

- Installation is easy.

- Extension is possible.

- Material can be reused.

Disadvantages of casing and capping wiring

- Costly wiring

- Difficult to locate the fault as the wires or cables are covered.

- In case of short circuit casing and capping can catch fire as they are made of Plastic.

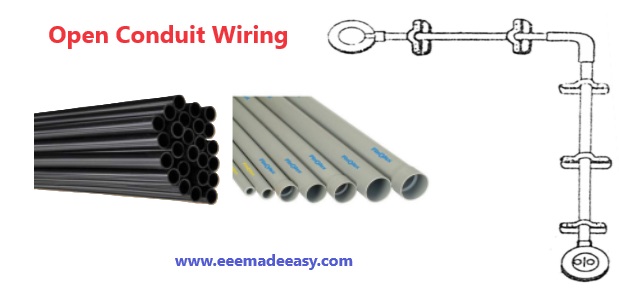

Conduit Wiring

There are two types of conduit wiring

- Open or External

- Internal or Concealed

P.V.C (Poly Vinyl Chloride) pipes are used for this type of wiring in which cable passes from one point to other point for electric supply within P.V.C. pipes.

Read also: Which IE rule is applicable to service mains?|Indian Electricity Rule

In internal wiring the pipe is fixed concealed in the roof and wall, while in open wiring the pipes are fixed on the wall with clips or saddle.

Accessories used in Conduit Wiring

- L-Bend

- T-Bend

- Junction Box

- Socket

- Saddle

Advantages of conduit wiring

- Wiring is water proof.

- Safe from mechanical damages.

- Look beautiful as it is concealed.

- Long life (approx 100 years).

Disadvantages of conduit wiring

- Difficult to locate the fault as the wires or cables are covered.

- Extension is difficult.

- Installation is difficult.

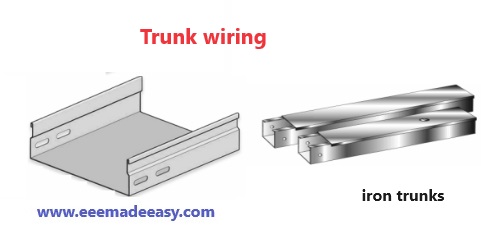

Trunking Wiring

- Trunking wiring is used for heavy voltage lines in substation and generation.

- Iron trunks are used for this wiring. Trunks available in circular or square shape.

- Couplers are used for jointing different lengths which fixed with screw.

- Trunking wiring is used mostly in developed cities.

Join EEE Made Easy Whatsapp Channel

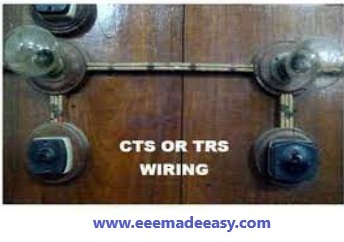

CTS or TRS or PVC Sheath Wiring

- CTS cables are available in single-core, twin-core or three-core with a circular or oval in shape.

- CTS cables are sufficiently chemical proof, water proof, steam proof.

- The cables are run or carried on well seasoned, perfectly straight and well varnished (on all four sides) teak wood batten of thickness 10 mm. at least.

- The width of the batten depends upon the number and size of cables to be carried by it. Battens are fixed to the walls or ceilings by means of gutties or wooden plugs.

- The cables are held on the wooden batten by means of tinned brass link clips spaced at an interval of 10 cm.

- .This system is suitable for low voltage installations.

Read More on Electrical Wiring

- Electrical Wiring Systems- Tree, Distribution

- Types of Electrical wiring

- IS 732- Code of Practice for Electrical Wiring Installations IS 732-1989

- [PDF]IE Rules|Indian Electricity Rules 1956

- Indian Electricity Rules MCQ|IE Rules Questions

- [Latest PDF] Electricity Act 2003|Indian Electricity Act 2003 PDF

- Ceiling Rose|Types, Price,Design Installation Electrical Ceiling Rose|IS 371- Bureau of Indian Standards 1999

- Wiring and Earthing MCQ- Electrical Engineering MCQ

- 7 Steps to Make Electrical Extension Box|How to make an extension wire box

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus