Fuse: A fuse is an electrical safety device that operates to provide overcurrent protection of an electrical circuit. The essential component of Fuse is a metal wire or strip that melts when too much current flows through it, thereby stopping or interrupting the current.

Fuse

A fuse is a short piece of wire or a thin strip of metal, which is inserted in series to the circuit.

When the fault current flows through the fuse for a sufficient time, it melts the fuse, thus isolating the circuit.

Join EEE Made Easy Telegram channel

Working of Fuse

Under normal operation, the fuse is kept at a temperature below the melting point of the material used, which helps in carrying the normal current without any rise in temperature.

But when fault occurs in the power system due to a short circuit or when an overload current, which is greater than the normal current, flows through the fuse, this fault current will increase the temperature above the melting point of the material used for the fuse.

Hence, the material melts or blows, thereby isolating the healthy part and protects the circuit.

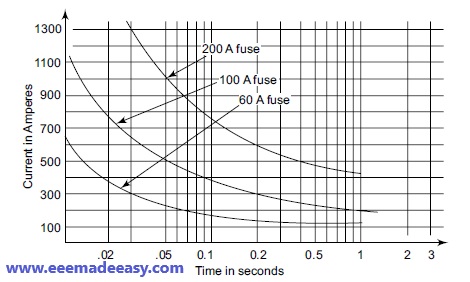

The magnitude of excessive current flowing in the circuit is an important factor in deciding the time taken for melting or blowing out the fuse.

Greater the fault current, lesser the time required to melt or blow out the fuse.

The inverse time-current characteristics of a fuse are shown in Figure below.

Advantages and Disadvantages of Fuse

The advantages and disadvantages of fuse are given as follows:

Advantages of Fuse

- Cheapest form of protection device.

- Requires no maintenance.

- Operation of fuse is completely automatic.

- Easily breaks a large amount of fault current.

- Pollution-free protection device i.e., does not create any smoke or noise.

- Suitable for over-current conditions due to its inverse current–time characteristics.

- Requires less time for isolating the faulty part of the circuit.

Disadvantages of Fuse

- Rewiring or replacing a fuse takes a considerable time.

- Discrimination between fuses connected in series is not possible.

- Correlation of the characteristics of fuse with the protected device is not always possible.

Download & Install EEE Made Easy App

Desirable Characteristics of Fuse Element Materials

The desirable characteristics of the material used for the fuse to perform satisfactorily are:

- Low melting point, e.g., tin, lead

- High conductivity, e.g., silver, copper

- Least reactive to oxidation, e.g., silver

- Affordable, e.g., lead, tin, copper

It can be noted that no element possesses all the desirable characteristics of a fuse and hence a compromise is to be made in selecting a material for the fuse.

Lead, tin, copper, zinc and silver are the most commonly used fuse materials.

Tin, or an alloy of lead and tin (0.37 and 0.63 respectively) is used as a fuse element material, where the rating of current is up to 10 A.

For larger currents, copper or silver is used as fuse element material. Usually, the copper is tinned to prevent oxidation effect.

Zinc, in strip form, is used where a considerable time-delay is required.

silver as a fuse element

In day-to-day activities, silver is used as a fuse element due to the following characteristics:

- Silver Does not get affected or deteriorate when used in dry air.

- As the expansion coefficient of silver is very small, it can carry the rated current continuously for a long time.

- Conductivity is very high.

- Instantaneous transition to vapour state from melting state, when compared to other materials, is possible due to low specific heat.

- Faster operation is possible at higher currents.

- Quick interruption of fault current is possible as the element vaporises at a temperature much lower than the temperature required to ionize it.

How to choose a Fuse?

The time-delay fuses for inductive load and fast acting fuses for the resistive load.

from the appliance manual, Check the power(watts) of the appliance ,voltage rating

The voltage must be greater than the circuit voltage for the proper protection of the device.

Fuse rating = (watts/volts) x 1.25

Use the next highest fuse rating after the calculation.

For example, if the calculated fuse rating is 8.634 Amps, so for this choose a 9 Amp fuse.

Important Terms Fuse

Following are the terms required in fuse analysis:

Current rating of fuse element

Current rating of fuse element is the amount of current that the fuse element can carry under normal operation, without overheating or melting. It depends on temperature rise in the fuse holder, the fuse material and the surroundings of the fuse.

Fusing current

Fusing current is the minimum current at which the fuse element melts or blows away and isolates the healthy portion of the power system.

It is higher than the current rating of the fuse element.

Fusing factor

Fusing factor is the ratio of the fusing current to the current rating of fuse element and its value

is always greater than 1.

Prospective current

Prospective current is the RMS value of the fault current, which is obtained by replacing the fuse with a conductor of negligible resistance.

Cut-off current of Fuse

Cut-off current is the maximum value of fault current obtained before the fuse element melts.

Pre-arcing time of Fuse

Pre-arcing time: The time taken to cut off the fault current from its commencement is known as pre-arcing time.

Arcing time of Fuse

Arcing time: The time taken to extinguish the arc after the pre-arcing time is known as arcing time.

Total operating time of Fuse

● Total operating time is the summation of pre-arcing and arcing time.

Breaking capacity

Breaking capacity: The RMS value of the maximum prospective current, which a fuse can deal at rated voltage, is known as breaking capacity.

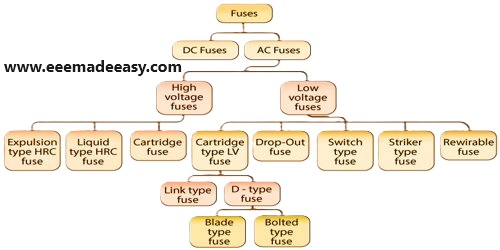

Types of Fuses

The general classification of fuses is given as follows:

- Low-voltage fuses

● Semi-enclosed re-wireable fuse

● High rupturing capacity (HRC) cartridge fuse with and without tripping device - High-voltage fuses

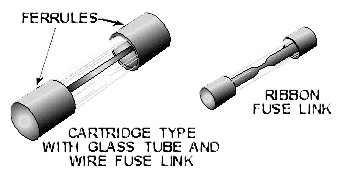

● Cartridge type

● Liquid type

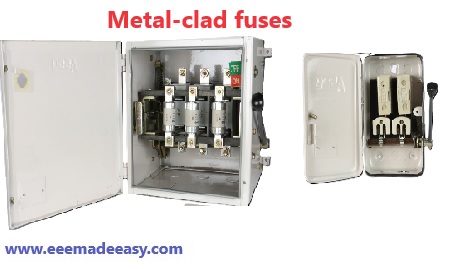

● Metal-clad fuses

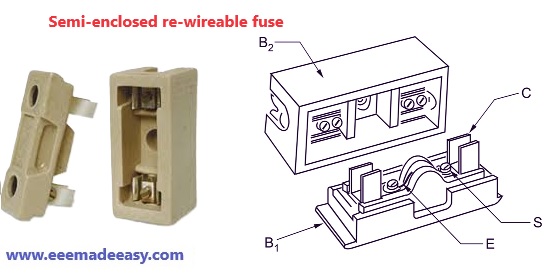

Semi-enclosed re-wireable fuse (Kit-Kat Fuse)

In this type the fuse element is semi–enclosed i.e. neither open nor totally closed

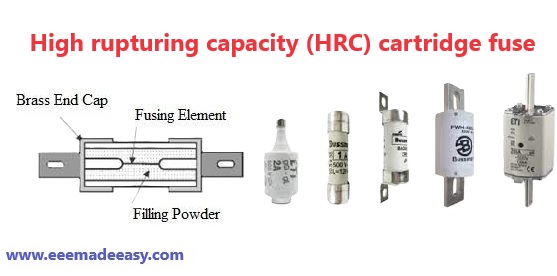

High rupturing capacity (HRC) cartridge fuse

Cartridge type Fuse

Liquid type Fuse

Metal-clad fuses

Comparison Between Circuit Breaker and Fus

| Specification | Circuit Breaker | Fuse |

|---|---|---|

| Function | Performs interruption function | Performs detection and interruption functions |

| Operation | Requires more equipment for automatic operation. | Requires less equipment for full automatic operation |

| Breaking capacity | Very large | Small |

| Operating time | Large (0–1 or 0–2 sec) | Very small (0.002 sec) |

| Replacement | It need not be replaced after its operation. | Requires continuous replacement after every operation. |

Read Also:

Difference between Fuse and Circuit breaker|Fuse vs Circuit Breaker

Difference between Isolator and Circuit breaker|Isolator Vs Circuit breaker

Latest Posts EEE Made Easy

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus