Resistors Types

In this post, we have explained types of resistors. There is another post on resistors. Read it HERE

Read Also : Types of Resistors

Join EEE Made Easy Telegram channel

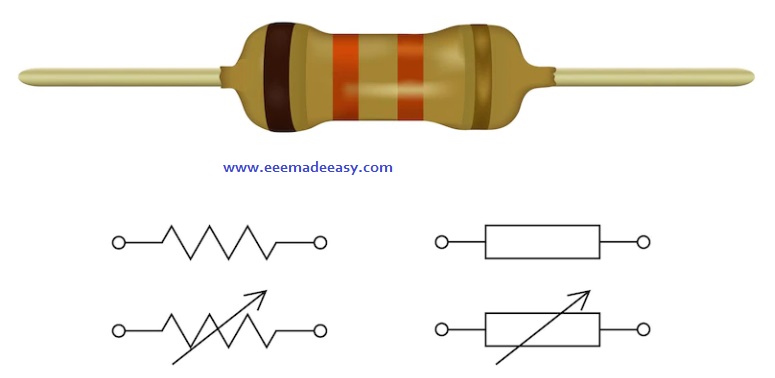

(a) Carbon Composition Resistors

It is a combination of carbon particles and a binding resin with different proportions for providing

desired resistance.

Attached to the ends of the resistive element are metal caps that have axial leads of tinned copper wire for soldering the resistor into a circuit.

The resistor is enclosed in a plastic case to prevent the entry of moisture and other harmful elements from outside.

Billions of carbon composition resistors are used in the electronic industry every year.

They are available in power ratings of 1/8, 1/4, 1/2, 1 and 2 W, in voltage ratings of 250, 350 and 500 V.

They have low failure rates when properly used.

Such resistors have a tendency to produce electric noise due to the current passing from one

carbon particle to another.

This noise appears in the form of a hiss in a loudspeaker connected to a hi-fi system and can overcome very weak signals.

That is why carbon composition resistors are used where performance requirements are not demanding and where low cost in the main consideration.

Hence, they are extensively used in entertainment electronics although better resistors are used in

critical circuits.

Read Also :

Resistance|Unit of Resistance|Conductance

Ohms’s law solved Problems|Problems based on ohm’s law

What is Ohm’s Law? Ohm’s Law Statement Formula Examples

(b) Deposited Carbon Resistors

Deposited carbon resistors consist of ceramic rods which have a carbon film deposited on them.

They are made by placing a ceramic rod in a methane-filled flask and heating it until, by a gas cracking process, a carbon film is deposited on them.

A helix-grinding process forms the resistive path.

As compared to carbon composition resistors, these resistors offer a major improvement in

lower current noise and in closer tolerance.

These resistors are being replaced by metal film and metal glaze resistors.

(c) High-Voltage Ink Film Resistors

These resistors consist of a ceramic base on which a special resistive ink is laid down in a helical

band.

These resistors are capable of withstanding high voltages and find extensive use in cathode-ray

circuits, in radar and in medical electronics.

Their resistances range from 1 kΩ to 100,000 MΩ with voltage range upto 1000 kV.

(d) Metal Film

Metal film resistors are made by depositing vaporized metal in vacuum on a ceramic-core rod.

The resistive path is helix-ground as in the case of deposited carbon resistors.

Metal film resistors have excellent tolerance and temperature coefficient and are extrememly reliable.

Hence, they are very suitable for numerous high grade applications as in low-level stages of certain instruments although they are much more costlier.

(e) Metal Glaze Resistors

A metal glaze resistor consists of a metal glass mixture which is applied as a thick film to a

ceramic substrate and then fired to form a film.

The value of resistance depends on the amount of metal in the mixture. With helix-grinding, the resistance can be made to vary from 1 Ω to many megaohms.

Another category of metal glaze resistors consists of a tinned oxide film on a glass substrate.

(f) Wire-wound Resistors

Wire-wound resistors are different from all other types in the sense that no film or resistive

coating is used in their construction.

They consist of a ceramic-core wound with a drawn wire having accurately-controlled characteristics.

Different wire alloys are used for providing different resistance ranges.

These resistors have highest stability and highest power rating.

Because of their bulk, high-power ratings and high cost, they are not suitable for low-cost or

high-density, limited-space applications.

The completed wire-wound resistor is coated with an insulating material such as baked enamel.

(g) Cermet (Ceramic Metal) Resistors

The cermet resistors are made by firing certain metals blended with ceramics on a ceramic substrate.

The value of resistance depends on the type of mix and its thickness.

These resistors have very

accurate resistance values and show high stability even under extreme temperatures.

Usually, they are produced as small rectangles having leads for being attached to printed circuit boards (PCB).

Nonlinear Resistors

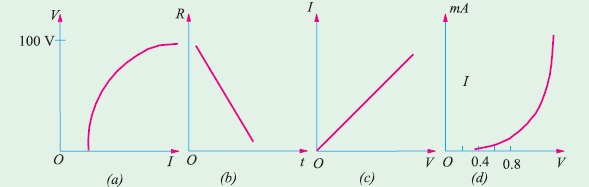

Those elements whose V − I curves are not straight lines are called nonlinear elements because

their resistances are nonlinear resistances.

Their V − I characteristics can be represented by a suitable equation.

Examples of nonlinear elements are filaments of incandescent lamps, diodes, thermistors and

varistors.

A varistor is a special resistor made of carborundum crystals held together by a binder.

Fig. (a) shows how current through a varistor increase rapidly when the applied voltage increases

beyond a certain amount (nearly 100 V in the present case).

There is a corresponding rapid decrease in resistance when the current increases.

Hence, varistors are generally used to provide over-voltage protection in certain circuits.

A thermistor is made of metallic oxides in a suitable binder and has a large negative coefficient

of resistance i.e., its resistance decreases with increase in temperature as shown in Fig. (b).

Fig. (c) shows how the resistance of an incandescent lamp increases with voltage whereas Fig.

(d) shows the V-I characteristics of a typical silicon diode.

For a germanium diode, current is related to its voltage by the relation.

I = Io [e^(V/0.026)− 1]

Download & Install EEE Made Easy App

Varistor (Nonlinear Resistor)

It is a voltage-dependent metal-oxide material whose resistance decreases sharply with increasing

voltage.

The relationship between the current flowing through a varistor and the voltage applied

across it is given by the relation : i = ke^η

where i = instantaneous current, e is the instantaneous voltage and η is a constant whose value depends on the metal oxides used.

The value of η for silicon-carbide-based varistors lies between 2 and 6 whereas zinc-oxide-based varistors have a value ranging from 25 to 50.

The zinc-oxide-based varistors are primarily used for protecting solid-state power supplies from

low and medium surge voltage in the supply line.

Silicon-carbide varistors provide protection against high-voltage surges caused by lightning and by the discharge of electromagnetic energy stored in the magnetic fields of large coils.

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus

- Basic Electrical Engineering Quiz | Cells and Batteries Quiz

- [PDF]RRB Technician Syllabus 2024| Exam Pattern RRB Technician

- Measurement of High Resistance

- HVDC vs HVAC |Comparison of HVAC and HVDC

- Electrical Distribution System