Energy audit: An energy audit is an inspection survey and an analysis of energy flows for energy conservation in a building. It may include a process or system to reduce the amount of energy input into the system without negatively affecting the output.

In commercial and industrial real estate, an energy audit is the first step in identifying opportunities to reduce energy expense and carbon footprint.

What is an energy audit?

An energy audit is an inspection, survey and analysis of energy flow for energy conservation in a building, processor system to reduce the amount of energy input into the system without negatively affecting the output(s).

Energy audit Principle

When the object of study is an occupied building then reducing energy consumption while maintaining or improving human comfort, health and safety are of primary concern.

Beyond simply identifying the sources of energy use, an energy audit seeks to prioritize the energy uses according to the greatest to least cost effective opportunities for energy savings.

Home energy audit

A home energy audit is a service where the energy efficiency of a house is evaluated by a person using professional equipment (such as blower doors and infrared cameras), with the aim of suggesting the best ways to improve energy efficiency in heating and cooling the house.

An energy audit of a home may involve recording various characteristics of the building envelope including the walls, ceilings, floors, doors, windows, and skylights.

For each of these components, the area and resistance to heat flow (R-value) is measured or estimated.

The leakage rate or infiltration of air through the building envelope is of concern, both of which are strongly affected by window construction and quality of door seals such as weatherstripping.

The goal of this exercise is to quantify the building’s overall thermal performance.

The audit may also assess the efficiency, physical condition, and programming of mechanical systems such as the heating, ventilation, air conditioning equipment, and thermostat.

A home energy audit may include a written report estimating energy use given local climate criteria, thermostat settings, roof overhang, and solar orientation.

This could show energy use for a given time period, say a year, and the impact of any suggested improvements per year.

The accuracy of energy estimates are greatly improved when the homeowner’s billing history is available showing the quantities of electricity, natural gas, fuel oil, or other energy sources consumed over a one or two-year period.

Some of the greatest effects on energy use are user behavior, climate, and age of the home.

An energy audit may therefore include an interview of the homeowners to understand their patterns of use over time.

The energy billing history from the local utility company can be calibrated using heating degree day and cooling degree day data obtained from recent, local weather data in combination with the thermal energy model of the building.

Advances in computer-based thermal modeling can take into account many variables affecting energy use.

A home energy audit is often used to identify cost-effective ways to improve the comfort and efficiency of buildings.

In addition, homes may qualify for energy efficiency grants from the central government.

Recently, the improvement of smartphone technology has enabled homeowners to perform relatively sophisticated energy audits of their own homes.

This technique has been identified as a method to accelerate energy efficiency improvements.

Industrial energy audit

Increasingly in the last several decades, industrial energy audits have exploded as the demand to lower increasingly expensive energy costs and move towards a sustainable future have made energy audits greatly important.

Their importance is magnified since energy spending is a major expense to industrial companies (energy spending accounts for ~ 10% of the average manufacturer’s expenses).

This growing trend should only continue as energy costs continue to rise.

While the overall concept is similar to a home or residential energy audit, industrial energy audits require a different skill set.

Weatherproofing and insulating a house are the main focus of residential energy audits.

For industrial applications, weatherproofing and insulating often are minor concerns.

In industrial energy audits, it is the HVAC, lighting, and production equipment that use the most energy.

Types of energy audit

The term energy audit is commonly used to describe a broad spectrum of energy studies .

It ranges from a quick walk-through of a facility to identify major problem areas to a comprehensive analysis of the implications of alternative energy efficiency measures sufficient to satisfy the financial criteria of sophisticated investors.

Numerous audit procedures have been developed for non-residential (tertiary) buildings (ASHRAE,IEA-ECBCS Annex Krarti,2000).

Audit is required to identify the most efficient and cost-effective Energy Conservation Opportunities (ECOs) or Measures (ECMs). Energy conservation opportunities (or measures) can consist in more efficient use or of partial or global replacement of the existing installation.

Issues of an energy audit

The main issues of an audit process are:

- The analysis of building and utility data, including study of the installed equipment and analysis of energy bills;

- The survey of the real operating conditions;

- The understanding of the building behavior and of the interactions with weather, occupancy and operating schedules;

- The selection and the evaluation of energy conservation measures;

- The estimation of energy saving potential;

- The identification of customer concerns and needs

Common types/levels of energy audits are distinguished below, although the actual tasks performed and level of effort may vary with the consultant providing services under these broad headings.

The only way to ensure that a proposed audit will meet your specific needs is to spell out those requirements in a detailed scope of work.

Taking the time to prepare a formal solicitation will also assure the building owner of receiving competitive and comparable proposals.

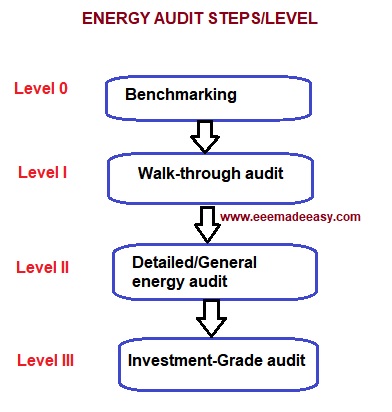

Generally, four levels of analysis can be outlined (ASHRAE)

- Level 0 – Benchmarking

- Level I – Walk-through audit

- Level II – Detailed/General energy audit

- Level III – Investment-Grade audit

Level 0 – Benchmarking

This first analysis consists in a preliminary Whole Building Energy Use (WBEU) analysis based on the analysis of the historic utility use and costs and the comparison of the performances of the buildings to those of similar buildings.

This benchmarking of the studied installation allows determining if further analysis is required;

Level I – Walk-through audit

Preliminary analysis made to assess building energy efficiency to identify not only simple and low-cost improvements but also a list of energy conservation measures (ECMs, or energy conservation opportunities, ECOs) to orient the future detailed audit.

This inspection is based on visual verifications, study of installed equipment and operating data and detailed analysis of recorded energy consumption collected during the benchmarking phase;

Level II – Detailed/General energy audit

Based on the results of the pre-audit, this type of energy audit consists in energy use survey in order to provide a comprehensive analysis of the studied installation, a more detailed analysis of the facility, a breakdown of the energy use and a first quantitative evaluation of the ECOs/ECMs selected to correct the defects or improve the existing installation.

This level of analysis can involve advanced on-site measurements and sophisticated computer-based simulation tools to evaluate precisely the selected energy retrofits.

Level III – Investment-Grade audit

Detailed Analysis of Capital-Intensive Modifications focusing on potential costly ECOs requiring rigorous engineering study.

Benchmarking

It is necessary to find a way of describing what constitutes good, average and bad energy performance across a range of situations.

The aim of benchmarking is to answer this question. Benchmarking mainly consists in comparing the measured consumption with reference consumption of other similar buildings or generated by simulation tools to identify excessive or unacceptable running costs.

As mentioned before, benchmarking is also necessary to identify buildings presenting interesting energy saving potential.

An important issue in benchmarking is the use of performance indexes to characterize the building.

Benchmark Indexes

These indexes can be:

- Comfort indexes, comparing the actual comfort conditions to the comfort requirements;

- Energy indexes, consisting in energy demands divided by heated/conditioned area, allowing comparison with reference values of the indexes coming from regulation or similar buildings;

- Energy demands, directly compared to “reference” energy demands generated by means of simulation tools.

Walk-through or preliminary audit

The preliminary audit (alternatively called a simple audit, screening audit or walk-through audit) is the simplest and quickest type of audit.

It involves minimal interviews with site-operating personnel, a brief review of facility utility bills and other operating data, and a walk-through of the facility to become familiar with the building operation and to identify any glaring areas of energy waste or inefficiency.

Typically, only major problem areas will be covered during this type of audit.

Corrective measures are briefly described, and quick estimates of implementation cost, potential operating cost savings, and simple payback periods are provided.

A list of energy conservation measures (ECMs, or energy conservation opportunities, ECOs) requiring further consideration is also provided.

This level of detail, while not sufficient for reaching a final decision on implementing proposed measure, is adequate to prioritize energy-efficiency projects and to determine the need for a more detailed audit.

General audit

The general audit (alternatively called a mini-audit, site energy audit or detailed energy audit or complete site energy audit) expands on the preliminary audit described above by collecting more detailed information about facility operation and by performing a more detailed evaluation of energy conservation measures.

Utility bills are collected for a 12 to 36 month period to allow the auditor to evaluate the facility’s energy demand rate structures and energy usage profiles.

If interval meter data is available, the detailed energy profiles that such data makes possible will typically be analyzed for signs of energy waste.

Additional metering of specific energy-consuming systems is often performed to supplement utility data.

In-depth interviews with facility operating personnel are conducted to provide a better understanding of major energy-consuming systems and to gain insight into short and longer term energy consumption patterns.

This type of audit will be able to identify all energy-conservation measures appropriate for the facility, given its operating parameters.

A detailed financial analysis is performed for each measure based on detailed implementation cost estimates; site-specific operating cost savings, and the customer’s investment criteria.

Sufficient detail is provided to justify project implementation.

Investment-grade audit

In most corporate settings, upgrades to a facility’s energy infrastructure must compete for capital funding with non-energy-related investments.

Both energy and non-energy investments are rated on a single set of financial criteria that generally stress the expected return on investment (ROI).

The projected operating savings from the implementation of energy projects must be developed such that they provide a high level of confidence.

In fact, investors often demand guaranteed savings.

The investment-grade audit expands on the detailed audit described above and relies on a complete engineering study in order to detail technical and economical issues necessary to justify the investment related to the transformations.

Simulation-based energy audit procedure for non-residential buildings

The following procedure proposes to make intensive use of modern BES tools at each step of the audit process, from benchmarking to detailed audit and financial study:

Benchmarking stage

While normalization is required to allow comparison between data recorded on the studied installation and reference values deduced from case studies or statistics.

The use of simulation models, to perform a code-compliant simulation of the installation under study, allows to assess directly the studied installation, without any normalization needed.

Indeed, applying a simulation-based benchmarking tool allows an individual normalization and allows avoiding size and climate normalization.

Preliminary audit stage: Global monthly consumptions are generally insufficient to allow an accurate understanding of the building’s behaviour.

Even if the analysis of the energy bills does not allow identifying with accuracy the different energy consumers present in the facility, the consumption records can be used to calibrate building and system simulation models.

To assess the existing system and to simulate correctly the building’s thermal behaviour, the simulation model has to be calibrated on the studied installation.

The iterations needed to perform the calibration of the model can also be fully integrated in the audit process and help in identifying required measurements and critical issues.

Detailed audit stage

At this stage, on-site measurements, sub-metering and monitoring data are used to refine the calibration of the BES tool.

Extensive attention is given to understanding not only the operating characteristics of all energy consuming systems, but also situations that cause load profile variations on short and longer term bases(e.g. daily, weekly, monthly, annual).

When the calibration criteria is satisfied, the savings related to the selected ECOs/ECMs can be quantified.

Investment-grade audit stage

At this stage, the results provided by the calibrated BES tool can be used to assess the selected ECOs/ECMs and orient the detailed engineering study.

Energy Audit Terms

Energy Conservation

Energy Conservation means steps taken to reduce and to use as much energy as necessary

through changing energy consumption behavior, e.g. Switching off lights when not in use.

Energy Efficiency

Energy Efficiency means using less energy to provide the same service/output, eg. Replacing

inefficient light bulbs with efficient ones.

Faulty

Faulty means an equipment not working or made correctly; having defects.

Potential savings

Potential savings means the actual reduction in operating expenses from the improved energy efficiency generated by an energy conservation or efficiency activity.

Retrofitting

Retrofitting means upgrading an existing system to improve energy efficiency.

Tariff

Tariff means the amount of money charge by the supplier (utility) per kWh for the use of

electrical energy.

Vampire Load

Vampire Load means the way power is consumed by electronic and electrical appliances while

they are switched off or in standby mode (consuming electricity at a cost but not doing any

work).

Energy Audit Instruments

| 1. | Flue Gas Analysers | Used for optimizing the combustion efficiency by measuring/monitoring the oxygen and CO levels in flue gas of boilers, furnaces etc. and calculation of CO2 percentage in excess air level and efficiency. |

| 2. | Temperature Indicators | Used for measuring temperatures of gases/air, liquids, slurries, semi solids, powders etc. Using different types of probes. |

| 3. | Infrared Thermometers | Used for measuring temperatures from a distance using infrared technology. |

| 4. | Thermal Insulation scanner | Used for measuring loss of energy in Kcal per unit area from hot/cold insulated surfaces. The total loss can be obtained by multiplying the total surface under study. |

| 5. | Steam Trap Monitor | Used for performance evaluation of steam Traps. |

| 6. | Conductivity Meter | Used for on the spot water analysis of the amount of dissolved solids in water. |

| 7. | pH meter | Used for on the spot analysis of effective acidity or alkalinity of a solution/water. Acidity /alkalinity water. |

| 8. | Thermo-hygrometer | Used for measurement of air velocity & humidification, ventilation, Air-conditioning and refrigeration systems etc. |

| 9. | Thermo-hygrometer | Used for measurement of humidity and temperature and the calculation of dew point to find out the heat being carried away by out going gases in industries. Where product drying requires hot air. |

| 10. | Ultrasonic Flow Meter | Used for measurement of flow of liquids through pipelines of various sizes through ultrasonic sensors mounted on the pipelines. |

| 11. | U-Tube Manometer | Used for measurement of differential pressure. |

| 12. | Digital Manometer | Used for measurement of differential pressure. |

| 13. | Visguage | Used for measurement of differential viscosity. |

| 14. | Used Lube Oil Test Kit | Used for testing lube oil. |

| 15. | Non-Contact Tachometer | Used for measurement of speed of rotation equipment. |

| 16. | Demand Analyser | Used for measurement and analysis of electrical load and demand control. |

| 17. | Power Analyser | Used for measurement and analysis of electrical Power. |

| 18. | Harmonic Analyser | Used for analysis of harmonics in power System. |

| 19. | Luxmeter | Used for measurement of illumination level. |

| 20. | Clip on Dig. Watt Meter | Used for measurement of power without interrupting the connections. |

| 21. | Clip on Dig. PF Meter | Used for measurement of power factor without interrupting the connection. |

| 22. | Clamp on amp. Meter | Used for measurement of current without Interrupting the connections. |

| 23. | Digital Multimeter | Used for measurement of voltage. Current and resistance. |

| 24. | Frequency Meter | Used for measurement of power supply frequency. |

- Industries Extension Officer Syllabus Kerala PSC|IEO 2024 Syllabus

- [PDF]Trade Instructor Gr.II Electroplating Syllabus Kerala PSC|92/2023 syllabus

- [PDF] Syllabus Assistant Engineer Electrical Harbour Engineering Kerala PSC

- Industries Extension Officer Kerala PSC Notification|IEO 2024

- Electricity Act 2003 Section 135

- Synchronous Motor Advantages, Disadvantages & Applications

- [Latest]Assistant Director industries and commerce Kerala PSC syllabus|630/2023 syllabus