Continuous Butter Making -Dairy Engineering-Technical Superintendent Milk Marketing Federation ltd

Continuous Butter Making

With increasing volume sales of Table butter, the dairy plants are now switching over from conventional batch butter making to continuous ones, ensuring consistent quality of product throughout the continuous run of the continuous butter making machine.

Methods of continuous butter making were introduced at the end of the 19th century.

The continuous butter making processes are of two main types:

I. Fritz and Senn methods

which employs a medium fat cream (40-45 %).

II. Methods involving production of high fat (> 80 %) cream.

These days, the Fritz process is most popular, although in USSR the Meleshin high fat cream method still appears to be widely used.

In India, all the continuous butter making machines (CBMM) operates on Fritz principle only

Principles of Continuous Butter Making

There are main three principles of continuous butter making which are dealt herein:

I. Flotation or Agglomeration:

The principle is the same as in the batch method, but the process is faster.

Agitation of cream and fine foam is developed by blades revolving at high speeds (2000 rpm); there is a very rapid (< 3 s) formation of fat globule clusters that become butter granules and are carried to working section, while the buttermilk is expelled continuously.

The resulting grains washed or unwashed are worked in a kneading section.

Applied in Contimab, Westphalia, Silkeborg machines.

II. Concentration or Inversion process:

Cream (30-40 % fat) is concentrated in a special separator to a fat content (80-82 %) close to that of butter.

After standardization, the concentrated butterfat is cooled and worked.

The concentrated cream being unstable, phase inversion takes place by cooling at the continuous churn intake, and mechanical friction provided by propulsion screws or agitators.

Applied in Alfa process (Sweden), New-way process (Australia) and Meleshin process (USSR).

III. Emulsion or Combination:

This involves the concentration of 30-40 % fat cream to fat content of 85-99 %; during concentration, the emulsion is broken.

Thereafter, standardization of the composition is carried out by the addition of water or an aqueous solution of salt in the oil phase, followed by re-emulsification, cooling and working.

Applied in Cherry-Burrell and Creamery Package (USA).

In this post, focus has been laid only on Fritz principle of continuous butter making since Indian dairy plants have adopted it.

Continuous machines are available for production capacities ranging from 200-10,000 kg of butter/h.

Continuous Butter Making By Fritz Process Preparation of cream:

The cream is prepared in the same way as for conventional churning (standardized to slight higher i.e. 45% fat, pasteurized, cooled and aged), before being continuously fed from the cream tank to the butter maker.

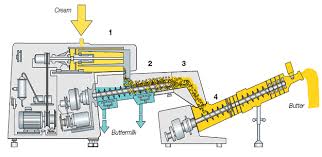

Churning of aged cream:

The cream is fed into a churning cylinder fitted with beaters that are driven by a variable-speed motor (~1000-3000 rpm).

This forms butter grains in about 2 sec. and the mixture of butter grains and buttermilk pass onto the next section.

Separating of buttermilk:

The section next to churning section consists of a perforated rotating (~ 35 rpm) drum, wherein the buttermilk is drained and collected separately, and the butter grains are consolidated due to the tumbling action of the cylinder.

Washing of butter grains:

The washing of the butter grains takes place en route with recirculated chilled buttermilk.

In some butter making machines, the butter granules are not washed with water.

Washing of butter granules and filter grids in Contimab machines with buttermilk at 2-4o C reduced-fat losses and improved butter quality.

By controlling the churning temperature through use of chilled water, the buttermilk fat content is kept to a minimum.

Working of butter and brine injection for salting:

The continuous butter maker may have one or even two working sections, depending on the manufacturer.

In case of machine with two working sections, the washed butter passes onto the first working section, wherein working is carried out under the action of two contra-rotating augers at adjustable speeds, followed by the perforated plates and impellor blades.

Both water and brine are usually injected before working in vacuum.

A metering pump (positive displacement pump) with a device for adjusting the flow rate distributes the salt uniformly in butter.

The strength of brine is about 50-60 % in order to obtain 2-3 % salt in the final product. The salt used in preparing brine should have particle size between 50-100 mm.

The colouring agent (annatto, β-carotene) may be added to the brine (but kept agitating during brine injection).

Vacuum working:

The worked butter then passed through a vacuum section (500-600 mm Hg in vacuum chamber) to obtain a denser, finer textured product with < 1 % air (without vacuum up to 8 % air may be present) incorporation.

Final working of butter:

The second set of augers in the second working section removes the butter from vacuum section and forces it through a further set of orifice plates and blades which completes emulsification.

Discharge of butter:

The machine may be set up to discharge directly into a bulk handling system i.e. feed hopper of a bulk packer.

Alternatively, a bulk butter silo maybe placed before the packaging machine. The butter pumps use large, interlocking rotors operating at low revolutions.

Packaging of butter:

The most efficient method of packing consumer portions is by direct feed from the buttermaker via a silo to the filler.

Most consumer butter packs use a film wrap – either vegetable parchment, or a parchment lined aluminium foil; final packing is done in a cardboard box (100 g, 500 g sizes).

Dairy Engineering More Notes

- Types of Dairies

- Importance of Dairy Plant Design

- Feeding System in Dairy Plant

- Classification of Dairy Plants

- Basic Principles of Evaporators

- Technical Superintendent Milma Syllabus

- Technical Superintendent Milma Previous Question paper

- Dairy Engineering MCQ questions 1

- Dairy Engineering MCQ questions 2

- Dairy Engineering MCQ questions 3

- Dairy Engineering MCQ questions 4

- The Technology of Milk and Milk products/ Technology of Butter making

- Butter making in Batch Churn

- Continuous Butter Making

- Ice cream FSSAI standards

- Indigenous Milk products Sweets

- Quality Assurance Standards of milk Products

- Air Heating Systems of Dairy Plant

| Basic Electrical Engineering MCQ’s From Notebook Site (www.notebukofaprofessor.blogspot.com) |

| 1. Basic Electrical Engineering MCQ 1 |

| 2. Current Electricity MCQ |

| 3. Basic Electrical MCQ 2 |

| 4. Basic Electrical Engineering MCQ 3 |

| 5. Basic Electrical Engineering MCQ 4 |

| 6. Basic Electrical Engineering MCQ 5 |

| 7. Basic Electrical Engineering MCQ 6 |

| 8. Basic Electrical Engineering MCQ 7 |

| 9. Basic Electrical Engineering MCQ 8 |

| 10. Basic Electrical Engineering MCQ 9 |

| 11. Basic Electrical Engineering MCQ 10 |

| 12. Basic Electrical Engineering MCQ 11 |

| 13. Basic Electrical Engineering MCQ 2 |

| 14. Basic Electrical Engineering MCQ 14 |